-

Cone crusher with choke feeding Ensure the crusher is consistently choke-fed, meaning the crushing chamber remains full. This increases multi-layer crushing, reduces liner wear, and improves output shape.

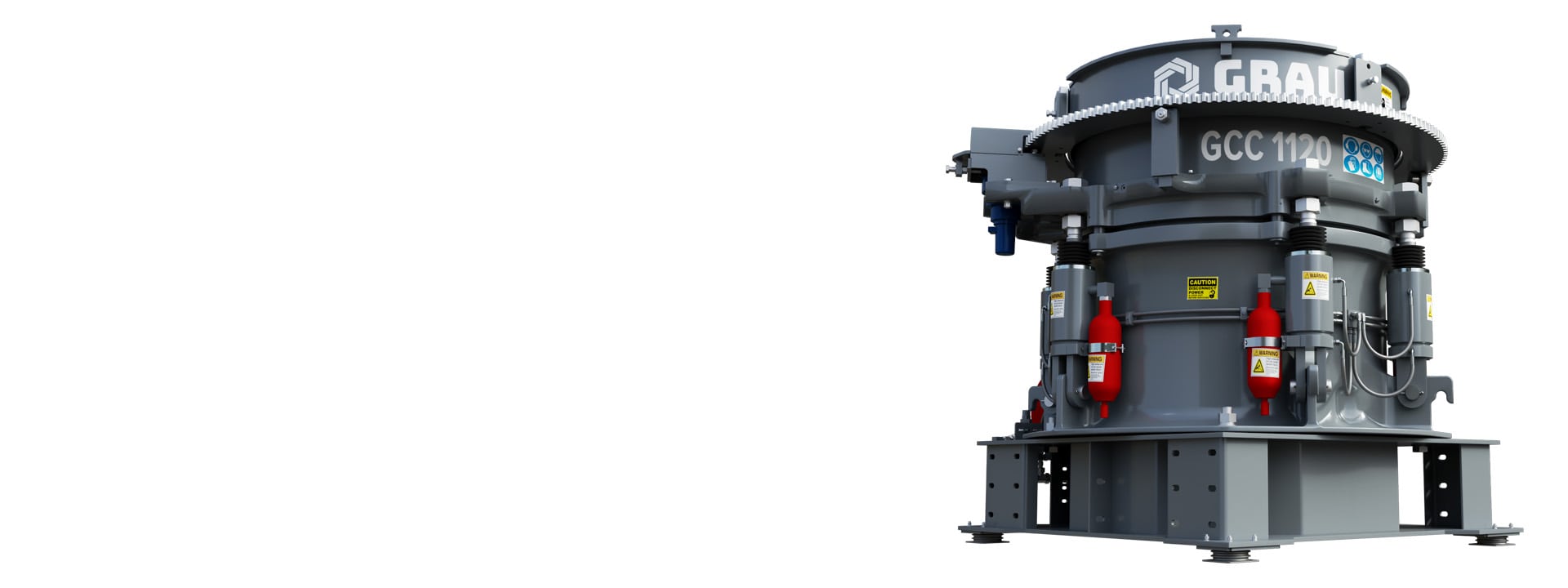

CONE CRUSHERS

GRAU CONE CRUSHERS: PROVEN CRUSHING TECHNOLOGY FOR HIGH-QUALITY AGGREGATES

GRAU Cone Crushers deliver high-performance crushing for secondary, tertiary, and quaternary applications in quarrying, aggregate processing, and other demanding industries. Available in stationary, mobile, and portable versions, GRAU cone rushers combine optimized crushing forces, throw and angular speed with a proven cavity design for high capacity and superior product quality. Built on principles of particle motion and inertia, they maximize stroke, power, and durability, enhancing particle-to-particle crushing for finer product shape, high reduction ratios, and increased output.

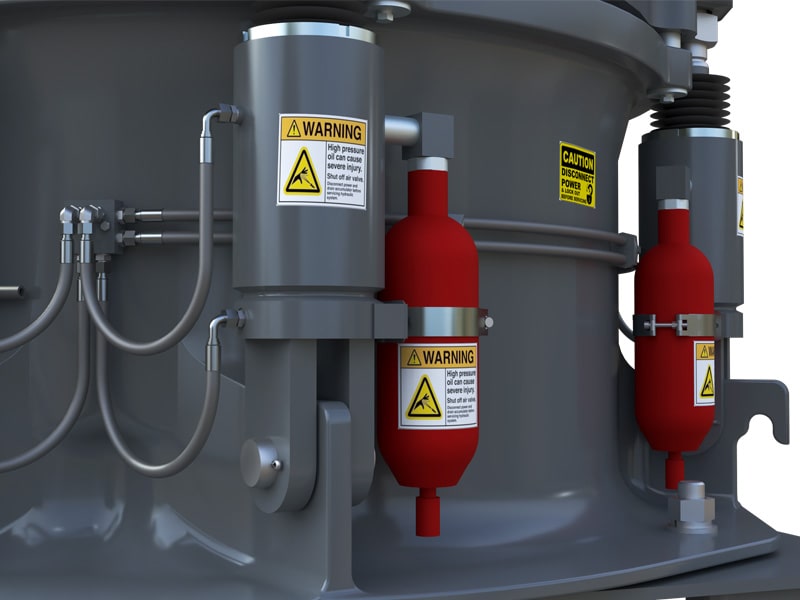

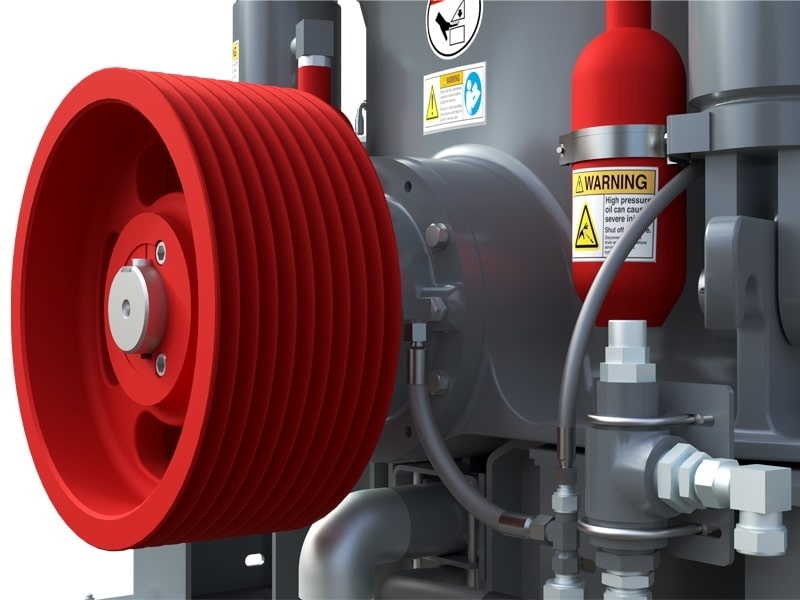

Equipped with efficient motors, GRAU cone crushers are both cost-effective and eco-friendly, using less energy to produce the exact required products. Designed for easy maintenance, they offer safety features like dual-acting hydraulic tramp-release cylinders, top access to components, and quick liner changes without backing compounds. The advanced hydraulic system and dual accumulators provide quick response for efficient tramp-iron passage and large clearing strokes when needed.

RELIABLE AND DURABLE SOLUTION

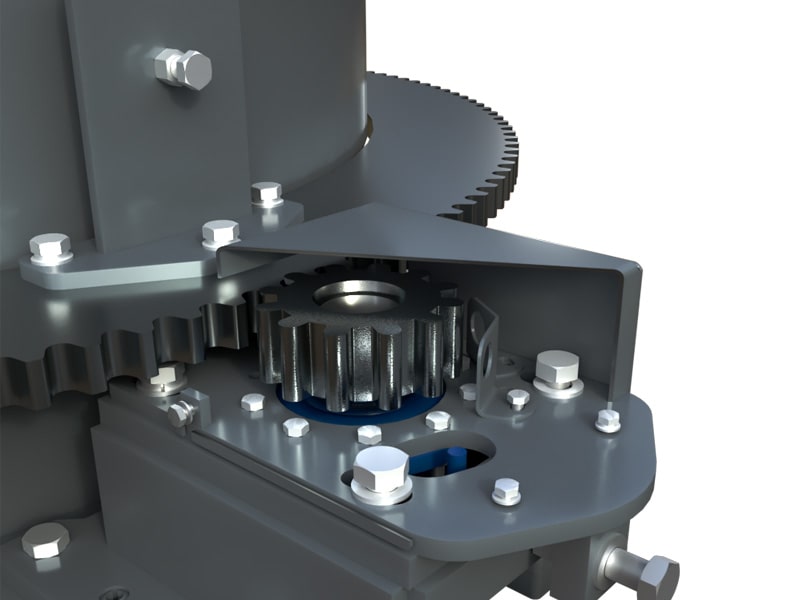

GRAU GCC Series Cone Crushers are highly efficient machines built with quality castings and durable fixings, offering a reliable solution for demanding applications. With a high-speed design that promotes longer service life, the GCC Series Cone Crushers minimize the need for shutdowns and replacement of parts, making it a highly cost-efficient choice. These cone crushers can produce large volumes of well-shaped aggregates and feature a precise CSS adjustment mechanism, allowing operators to set exact closed-side settings for consistent output quality. Equipped with a proven tramp iron relief system - including tramp relief cylinders and accumulators - the GCC Series Cone Crushers protect themselves from uncrushable material while automatically resetting to maintain the desired CSS, ensuring consistent product quality. All GRAU Cone Crushers are supplied with complete lubrication systems and, depending on the liner selection, can operate as a secondary, tertiary or quaternary crusher, adding versatility to your operations.

WHAT IS A CONE CRUSHER?

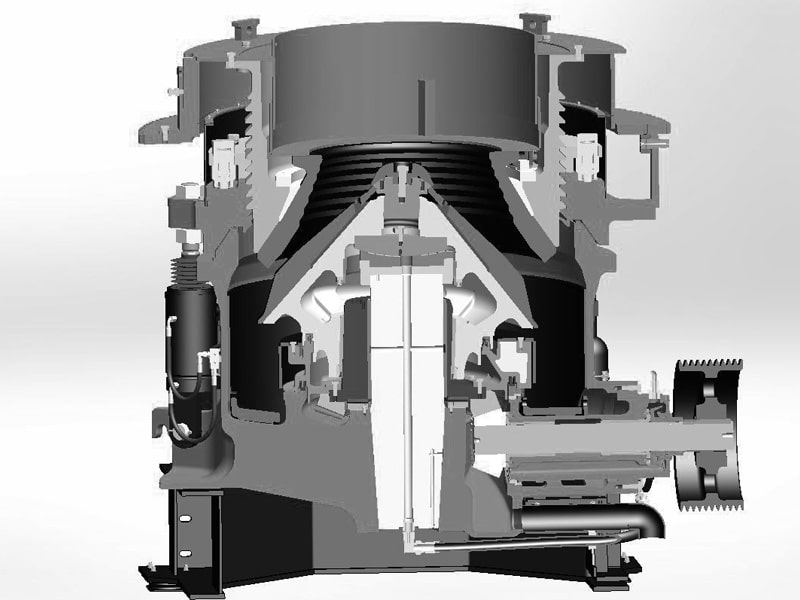

A cone crusher operates on principles of physics, specifically compression forces, to break down hard materials like granite or hard ores. At its core, the crusher consists of a stationary bowl liner and a moving mantle. When material enters the chamber, it gets caught between the mantle, which oscillates, and the bowl liner, which remains fixed. This oscillating movement creates a series of compressive forces that act on the material in a cyclical manner, breaking it down layer by layer through both direct and inter-particle crushing.

Physics Behind the Cone Crusher Crushing Process

- Compression and Shear Forces: The primary force in a cone crusher is compression, but shear forces also play a role. As the mantle moves closer to the bowl liner, it compresses the material against the liner surface, fracturing the material due to intense pressure. This compression force must be strong enough to exceed the material's internal bonds, causing it to fracture along its weakest points.

- Impact of Eccentric Throw: The eccentric throw in a cone crusher - essentially, the distance the mantle moves from its axis during operation - determines the rate and angle at which material is crushed. A larger eccentric throw increases the intensity of each compression cycle, enhancing the crushing effect, while a smaller throw allows for finer, more controlled particle reduction. By carefully adjusting the eccentric throw, operators can fine-tune the particle size and shape of the output.

- Kinematics of the Crushing Chamber: The mantle's movement is powered by an eccentric shaft, creating a gyrating motion that forces material through the chamber. This gyration is what causes the material to be crushed not only by direct compression between the liner and mantle but also by inter-particle comminution. Inter-particle comminution occurs when particles collide with each other as they are compressed between surfaces, effectively creating multiple breakage points. This is why this type of crushers must be choke-fed as this is the key in producing a uniform and cubical final product.

- Nip Angle and Friction: The nip angle is the angle between the mantle and the bowl liner. It plays a critical role in gripping the material within the chamber. An optimal nip angle maximizes friction between the material and crusher surfaces, reducing slippage and ensuring efficient compression. If the angle is too large, the material may slip back instead of being crushed, reducing efficiency and increasing wear on the machine.

- Energy Efficiency through Compression: Compared to impact crushers, cone crushers are more energy-efficient because they rely on compression rather than high-speed impact forces to break the material. The physics of compression requires less energy per ton of material processed, especially when the crusher is choke-fed (kept full at all times), which maximizes the efficiency of each compression cycle.

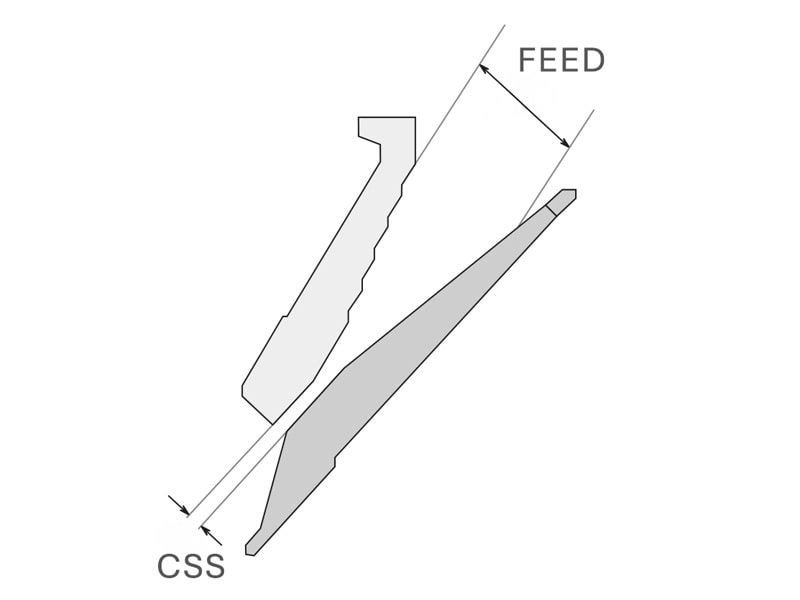

- Gradation and Reduction Ratio: The physics of the reduction ratio - essentially the relationship between the size of the input and output material - is influenced by the closed side setting (CSS) and open side setting (OSS). CSS is the tightest gap, dictating the minimum particle discharge size, while OSS is the largest opening, controlling the maximum particle feed size. These settings allow for precise control over the material size, ensuring consistent product gradation, which is critical in many construction applications.

-

01 RELIABLE -

02 TRAMP IRON RELIEF SYSTEM -

03 EASY ACCESS & MAINTENANCE

-

High Throughput Capacity Thanks to the unique combination of high speed and optimized throw, GRAU CSS Series cone crushers deliver very good throughput, allowing more material to be processed efficiently. -

Durable Tramp Release System The hydraulic tramp release system prevents equipment damage by automatically clearing uncrushable materials like tramp iron, reducing downtime and ensuring smooth operation.

-

Simplified Maintenance The crusher’s top-access design allows easy access to components, and features like hydraulic motors for setting adjustments make maintenance faster and more straightforward. -

Compact, Space-Efficient Design With their compact footprint, GRAU CSS Series cone crushers maximize space efficiency, making them suitable for operations with limited floor space while still delivering high productivity.

-

Consistent, High-Quality Product Shape Utilizing interparticle crushing action, these crushers produce a cubical final product with minimal fines, ideal for applications requiring high-quality aggregates and sand.

-

Operating a Cone Crusher: Distribute Feed Evenly Make sure feed material is spread evenly across the chamber, as uneven distribution can cause force cycles and power fluctuations, leading to inconsistent crushing performance.

-

Operating a Cone Crusher: Optimize Closed Side Setting (CSS): Regularly check and adjust CSS to maintain a stable reduction ratio and desired product size. A larger CSS setting increases capacity but can reduce power draw, while a smaller CSS setting produces finer output.

-

Operating a Cone Crusher: Monitor Power Draw and Operating Speed Operating at the lower end of the speed range allows for finer gradation, while higher speeds increase throughput. Aim for a steady power draw to avoid strain on components and ensure consistent performance.

-

Operating a Cone Crusher: Regularly Inspect Wear Patterns Track wear on the mantle and bowl liners. Uneven wear patterns indicate issues with feed distribution or chamber settings, which, if corrected, can reduce downtime and improve longevity.

| Model | Head Diameter (mm, inch) | Motor Power (kw, HP) | Crusher Weight (kg, lbs) | Pinion Speed, rpm | Capacity (up to Mtph, Stph) | ||||

| GCC 735 | 735 | 29 | 90 | 125 | 6,500 | 14,330 | 750-1200 | 155 | 170 |

| GCC 940 | 940 | 37 | 160 | 215 | 12,200 | 26,900 | 750-1200 | 440 | 485 |

| GCC 1120 | 1,120 | 44 | 220 | 300 | 18,100 | 39,900 | 750-1200 | 630 | 700 |

| GCC 1320 | 1,320 | 52 | 315 | 400 | 25,600 | 56,440 | 700-1000 | 790 | 870 |

Capacity

|

Model

|

Crusher Capacity (t/h) corresponding to CSS (mm)

|

|||||||||||

|

|

6

|

8

|

10

|

13

|

16

|

19

|

22

|

25

|

32

|

38

|

45

|

51

|

|

GCC 735

|

45-55

|

50-60

|

55-70

|

60-80

|

70-90

|

75-95

|

80-100

|

85-110

|

100-140

|

|

|

|

|

GCC 940

|

|

|

90-120

|

120-150

|

140-180

|

150-190

|

160-200

|

170-220

|

190-235

|

210-250

|

|

|

|

GCC 1120

|

|

|

115-140

|

150-185

|

180-220

|

200-240

|

220-260

|

230-280

|

250-320

|

300-380

|

350-440

|

|

|

GCC 1320

|

|

|

|

185-230

|

225-280

|

255-320

|

275-345

|

295-370

|

325-430

|

360-490

|

410-560

|

465-630

|