-

Maintenance Tips: Monitor Vibration Frequency and Amplitude Variations in vibration patterns may indicate issues with the motor or drive components. Monitoring frequency and amplitude at each side of the screen can help identify and resolve potential issues before they become critical. Please speak to one of our engineers if you would like to learn how to do it.

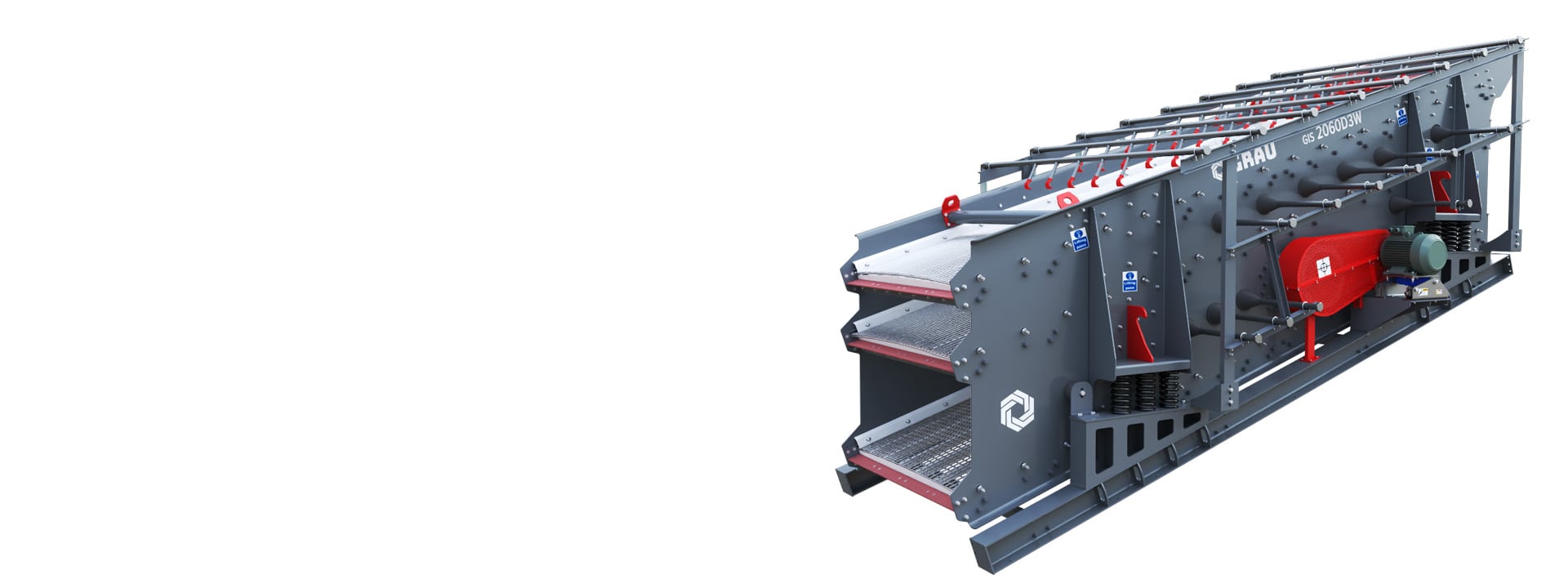

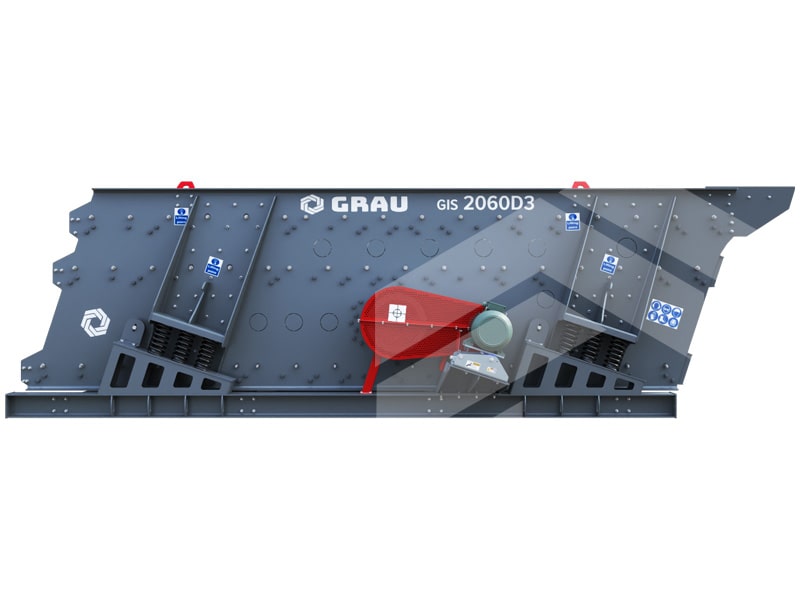

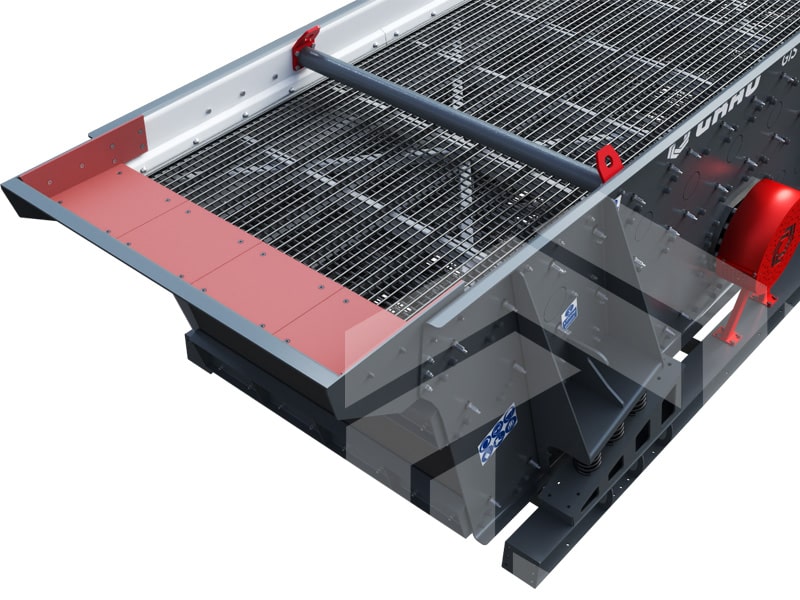

INCLINED SCREEN

GRAU INCLINED SCREENS

GRAU inclined vibrating screens are specially crafted with the operator in mind, emphasizing ease of use, simplified maintenance, and optimal performance. Our screens are designed to deliver the perfect circular motion for superior screening efficiency, regardless of material type or volume.

WHAT IS AN INCLINED VIBRATING SCREEN?

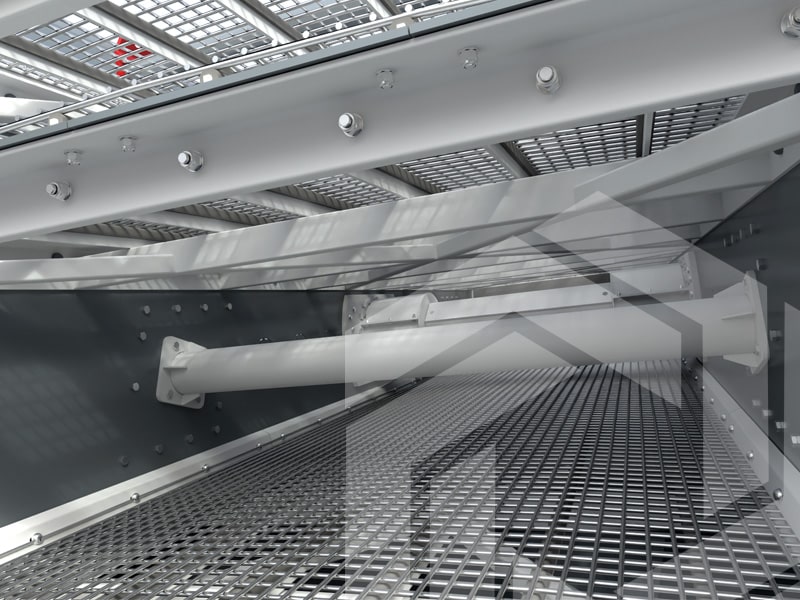

An inclined vibrating screen consists of a few screening decks (minimum 2) made as braced steel frames along the screen length, which are connected to side walls forming the main chassis of the screen, also referred to as the “screen box”. The screen’s deck surface is angled to promote the movement of material, ensuring that particles travel across the screen with ease. This is the main reason this type of screens in called “inclined”. The surface of each deck is covered with different types of meshes (woven wire, polyurethane, rubber, anti-clogging or pitched steel plates) with small holes that represent what size material passes through the screen onto the lower deck. The material that doesn’t fall to the deck below is screened off as per size of the mesh.

HOW DO INCLINED VIBRATING SCREENS WORK?

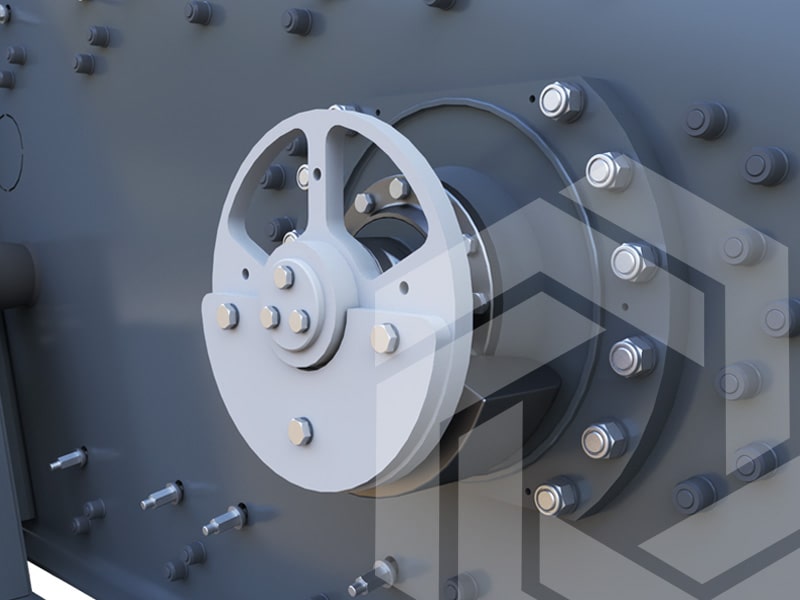

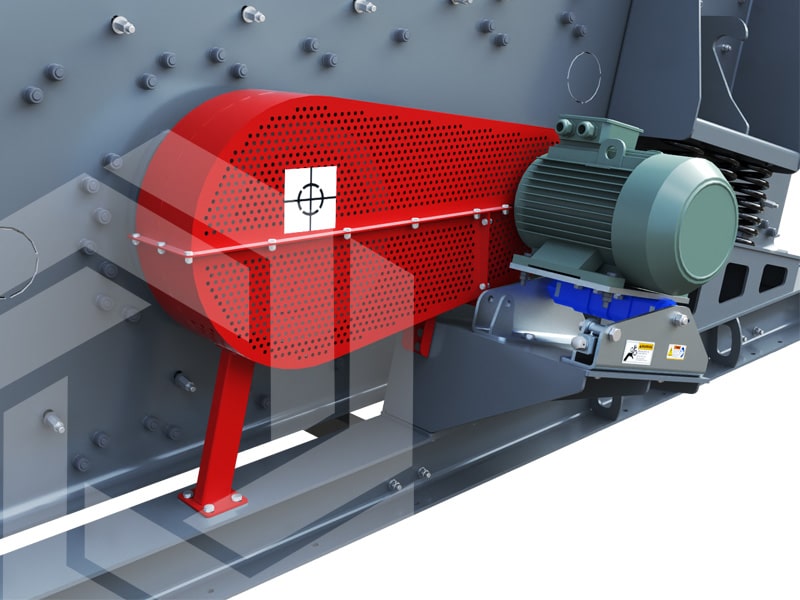

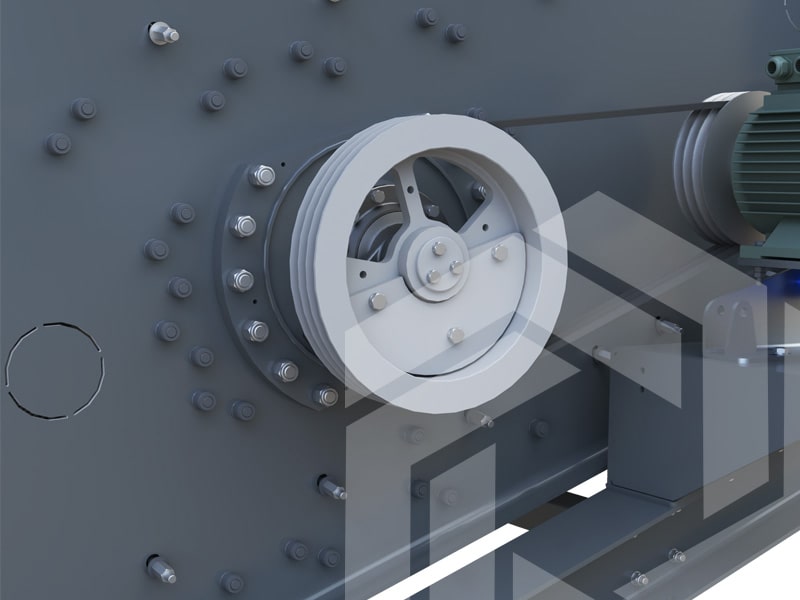

The inclined vibrating screens are powered by an electric motor that rotates eccentric drive mechanisms on both sides of the screen, connected by a shaft (cardan shaft in GRAU GIS series). These counterweights generate powerful circular vibrations that allow smaller particles to pass through while larger particles are carried over the screen deck surface. Screened material gets separated into {number of decks} + 1 flows and each flow gets discharged into different chutes.

WHAT ARE THE INCLINED VIBRATING SCREENS USED FOR?

- Screening

- Sizing

- Separating

- Grading

- Shifting

- Washing

WHAT ARE THE MAIN APPLICATIONS OF GRAU INCLINED SCREENS?

GRAU inclined vibrating screens offer versatile solutions across numerous industries:

- Aggregate Processing: GRAU inclined screens separate aggregates like sand, gravel, and crushed stone with precision, delivering well-graded materials for construction.

- Mining: Ideal for sorting valuable minerals, GRAU inclined screens handle heavy-duty materials like coal, iron ore, and precious metals with high efficiency.

- Recycling: GRAU inclined screens aid in sorting mixed materials, improving recycling rates and reducing contamination.

- Chemical Processing: GRAU inclined screens support separation needs in the chemical industry, reducing waste and enhancing quality control.

-

01 RELIABLE -

02 MODULAR DRIVE SYSTEM -

03 HUCK-BOLT DESIGN

-

GRAU INCLINED SCREENS GRAU GIS series inclined vibrating screens offer efficient material separation for mining, aggregate processing and recycling sectors. They feature perfect circular motion, modular drives, huck-bolt design, and various screen media options. Models vary in deck dimensions, number of decks, motor power, and weight, with options prepared for wet processing. -

Transport-Friendly Subframe The optional transport-friendly subframe makes transporting and installing GRAU inclined screens seamless, ensuring that ay screen box can be easily transported and installed/retrofitted without compromising on stability or durability.

-

Adaptable for Modular Screen Media GRAU inclined screens can easily adapt to various types of screen media, including polyurethane panels, screen mesh, anti-clogging mesh, wear-resistant pitched plates and modular type pinned screen media. This enhances flexibility, allowing the screen to be customized to suit different materials and applications. -

Durable Wear Plates in Feeding Zone Our vibrating screens are equipped with high-strength wear plates in the feeding zone, providing enhanced protection against abrasion and extending the lifespan of the equipment in high-impact areas.

-

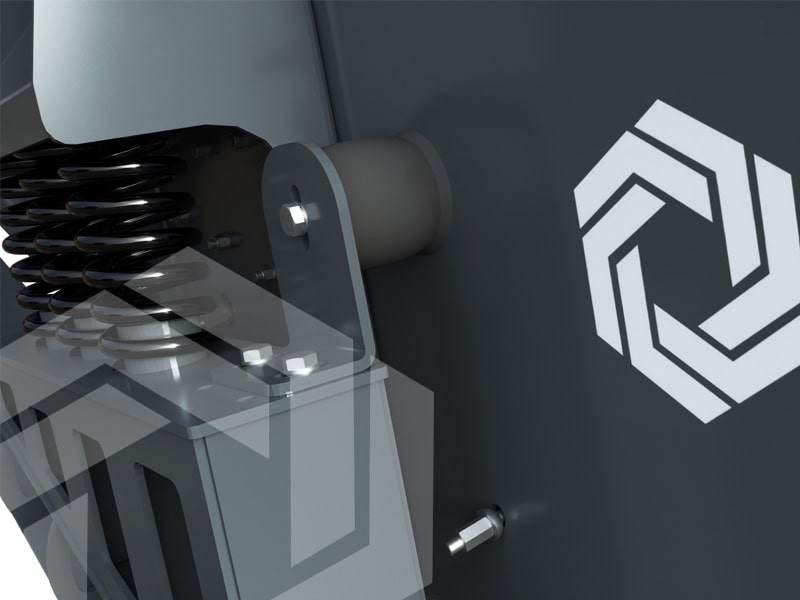

Modular Drive System for Easy Transport and Servicing GRAU modular drive system simplifies transportation and servicing, allowing operators to remove and reassemble drive system components quickly. This modular approach not only eases and reduces the transport cost but also cuts downtime and reduces on-site maintenance costs. -

Self-Tensioned Motor Base Our self-tensioned motor base reduces vibrations and minimizes stress on the drive components, especially during the start-stop cycles, extending the life of the motor and maintaining consistent, high-powered operation.

-

Prepared for Wet Processing GRAU inclined screens come with pre-cut holes that allow for straightforward conversion to washing configurations. This feature makes it simple to add water nozzles and adapt the screen for wet processing, enhancing material processing capabilities. GRAU GIS Wet inclined screens ensure efficient removal of unwanted fines, silt, and clay from aggregates and minerals, providing cleaner, high-quality output. -

Huck-Bolt Design for Maximum Durability The Huck-bolts don’t get lose. This setup doesn’t require frequent tightening of bolts which provides unmatched structural integrity, ensuring GRAU inclined screens maintain durability and performance across years of continuous use.

-

Side Snubbers to Eliminate Side Movements Side snubbers on GRAU inclined screens prevent unwanted lateral movement, ensuring stable, controlled operation and reducing wear on the bearings and screen structure over time.

-

Maintenance Tips: Regularly Inspect Screen Media for Wear Frequent checks for wear and tear in screen media prevent material leakage and inefficiency. Replacing worn sections prolongs the life of the screen and improves separation quality.

-

Maintenance Tips: Lubricate Bearings and Drive Components Bearings and drive mechanisms should be lubricated as recommended in our manual to prevent excessive wear. High-temperature and heavy-duty lubricants can offer added protection for intense applications.

-

Maintenance Tips: Inspect and Clean the Screen Surface Regularly Material buildup can reduce screening efficiency. Regular cleaning, especially for sticky or damp materials, ensures maximum throughput and extends screen life.

-

Maintenance Tips: Check for Loose Fasteners and Bolts While the main frame is fixed with huck-bolts, vibration over time can loosen bolts and fasteners of screen tensioning fixings. Regularly inspecting and tightening these elements ensures structural integrity and reduces unexpected downtimes.

MODEL |

Deck Dimensions |

Decks |

Motor Power |

Weight |

Wet Processing |

|||

mm |

ft |

kW |

HP |

kg |

lbs |

|||

GIS 1240D2 |

1200x4000 | 4'x13' | 2 | 7.5 | 10 | 3155 | 6955 | Prepared |

GIS 1240D3 |

1200x4000 | 4'x13' | 3 | 7.5 | 10 | 3960 | 8730 | Prepared |

GIS 1240D4 |

1200x4000 | 4'x13' | 4 | 7.5 | 10 | 4465 | 9840 | Prepared |

GIS 1540D2 |

1500x4000 | 5'x13' | 2 | 15 | 20 | 4255 | 9380 | Prepared |

GIS 1540D3 |

1500x4000 | 5'x13' | 3 | 15 | 20 | 4860 | 10715 | Prepared |

GIS 1540D4 |

1500x4000 | 5'x13' | 4 | 15 | 20 | 5365 | 11825 | Prepared |

GIS 1650D2 |

1600x5000 | 5.25'16.5' | 2 | 15 | 20 | 4855 | 10705 | Prepared |

GIS 1650D3 |

1600x5000 | 5.25'16.5' | 3 | 15 | 20 | 5560 | 12255 | Prepared |

GIS 1650D4 |

1600x5000 | 5.25'16.5' | 4 | 15 | 20 | 6565 | 14475 | Prepared |

GIS 2050D2 |

2000x5000 | 6.5'x16.5' | 2 | 18.5 | 25 | 6055 | 13350 | Prepared |

GIS 2050D3 |

2000x5000 | 6.5'x16.5' | 3 | 18.5 | 25 | 7060 | 15565 | Prepared |

GIS 2050D4 |

2000x5000 | 6.5'x16.5' | 4 | 18.5 | 25 | 8265 | 18220 | Prepared |

GIS 2060D3 |

2000x6000 | 6.5'x20' | 2 | 18.5 | 25 | 6655 | 14670 | Prepared |

GIS 2060D3 |

2000x6000 | 6.5'x20' | 3 | 22 | 30 | 7960 | 17550 | Prepared |

GIS 2060D4 |

2000x6000 | 6.5'x20' | 4 | 22 | 30 | 8865 | 19545 | Prepared |

GIS 2460D3 |

2400x6000 | 8'x20' | 3 | 30 | 40 | 8260 | 18210 | Prepared |

GIS 2460D4 |

2400x6000 | 8'x20' | 4 | 30 | 40 | 10565 | 23290 | Prepared |