-

Maintenance Tips: Perform Daily Inspections Before each production shift, check all key components – mixer, conveyors, belts, aggregate bins, and cement silos – for wear, leaks, or blockages. Identifying small issues early helps prevent costly downtime later.

GRAU MOBILE CONCRETE PLANTS

RELIABLE, HIGH-PERFORMANCE CONCRETE PRODUCTION ON THE MOVE

GRAU Mobile Concrete Batching Plants are engineered for fast, flexible, and efficient concrete production wherever it’s needed. Designed for rapid setup and relocation, our mobile concrete batch plants combine robust mobile steel frame on wheelbase with high-capacity production performance, making them ideal for temporary sites, remote locations, and projects with changing job sites.

Each model integrates all the essential components – aggregate storage, weighing systems, concrete mixer, cement silos, and control system – into a compact, transportable structure. This reduces installation time, minimises civil works, and allows companies to start production quickly. With precise batching accuracy, low maintenance requirements, and strong mobility features, GRAU Mobile Concrete Plants offer the same reliability and output as fixed plants, but with the added benefit of mobility..

EASY TRANSPORT AND RELOCATION

Many companies prefer mobile concrete plant solutions for temporary construction sites as installing and relocating a concrete production facility after a project has been completed is not an easy job. Keeping that in mind, we have developed our quick-erect mobile concrete plant product line to make sure our customers get the necessary flexibility while saving a lot of time.

WHAT IS A MOBILE CONCRETE BATCHING PLANT?

A mobile concrete plant is a fully transportable concrete batching facility that combines aggregate storage, cement silos, conveyors, weighing systems, and a high-performance mixer into a compact, movable structure designed for fast setup and relocation. Unlike stationary concrete plants, a mobile concrete batch plant requires minimal foundations and civil works, allowing it to be installed directly on-site to produce fresh, high-quality concrete exactly where it is needed. This reduces transport costs, eliminates delivery delays, and ensures consistent concrete performance for projects such as roads, bridges, infrastructure works, and temporary construction sites. By offering the same accuracy, productivity, and automation as a fixed plant with the added benefit of mobility, a mobile concrete plant provides the most efficient and flexible solution for modern construction demands.

WHAT DOES A MOBILE CONCRETE PLANT CONSIST OF?

A typical mobile concrete batch plant includes:

- Main Chassis on Wheelbase

- Aggregate Bins for storing and feeding the aggregates.

- Aggregate Weigh Hopper to precisely batch aggregates according to the recipe.

- Aggregate Transfer Conveyor for material transfer from the aggregate weigh bin into the concrete mixer.

- Integrated Cement/Binder Silos for storing cement and other powders, complete with all silo equipment, safety systems and filters.

- Weighing Systems for cement, water, additives and other mix components to ensure precise batching.

- Concrete Mixer (twin-shaft, single-shaft or planetary) for homogenous high-quality mixing.

- Control System for automated or manual operation of the plant.

- Service Platforms and Handrails for maintenance and servicing.

-

01 UP TO 120 m³/h -

02 EASY TRANSPORT -

03 FAST INSTALLATION

-

Move Your Plant in Days GRAU Mobile Concrete Plants will give you the flexibility you need. Our range allows you to disassemble, move the plant to a new site and set up concrete production in a matter of just a few days! We offer a unique design with folding aggregate bin walls and service platforms, which speed up the installation. All other components can be transported on the main chassis without the need for additional trucks. -

Service Friendly Main Frame We collaborate closely with operators and fitters to enhance our products, ensuring that servicing is safe and hassle-free. The main frames on our mobile concrete plants are specifically designed for ease of maintenance. Wide service platforms and straightforward access to mixer components, greasing points, and drip trays is essential and well-designed.

-

Robust Wheelbase GRAU Mobile Concrete Plants can be transported many times during their lifetime. Our robust wheelbase can sustain multiple relocations on rough site terrain for many years ahead. The wheelbase is equipped with air brakes, that can be easily connected to the truck’s braking system, and ABS (Antilock Brake System) that prevents the wheels from locking during braking and skidding. -

Unique Independent Weighing Hopper The aggregate bins on GRAU Mobile Concrete Plants are equipped with an independent aggregate weigh hopper, while other manufacturers weigh on the transfer belt itself. This setup allows for the next batch to start while the material is still moving on the transfer belt conveyor into the mixer. It results in higher production capacity and lower power consumption because transfer belt doesn’t start up with material on it. It is especially important when the plant is running on generator.

-

Mini Mobile Solutions Some projects require very low amounts of concrete and yet it is not easy to deliver concrete from other suppliers. We offer a cost-effective solution for such requirements. Discover our mini mobile solutions for on-site concrete production. Mini does not mean small and with up to 1 m³ capacity concrete mixers, these little machines can reach significant practical capacity of up to 45 m³/h.

-

Maintenance Tips: Keep the Mixer Clean Thoroughly clean the mixer drum and shafts at the end of each workday or if the plant stops briefly and will not be producing concrete for over 30 minutes. Simply add some coarse aggregates and water and mix it for a few minutes to clean the shafts and the body and use a manual jet wash to clean the rest. Consider installing an automatic mixer washout system. Hardened concrete buildup can affect mixing quality, reduce capacity, and increase load on the components.

-

Maintenance Tips: Check Calibrations Regularly Regularly verify the accuracy of all weighing systems for aggregates, cement, water, and additives. Correct calibration ensures consistent concrete quality and prevents mix design deviations. Remember that readings can drift slightly with significant temperature changes – for example, when conditions shift from very hot to near freezing – so recalibration may be necessary after major weather fluctuations.

-

Maintenance Tip: Lubricate Moving Parts as Recommended Follow the manufacturer’s lubrication schedule for bearings, shafts, and other moving parts. Proper lubrication reduces friction, prevents premature wear, and ensures smooth operation. Twinshaft concrete mixers have additional manual greasing points as automatic lubrication system are generally used to create pressure inside the labyrinth seals to keep concrete away.

-

Easy to Service and Maintain All GRAU mobile concrete plants come with wide service platforms and safe walkways fitted with handrails along the aggregate transfer belts. Conveyor belts are enclosed with cladding to help contain dust and reduce environmental impact, ensuring cleaner and safer operation on every site.

-

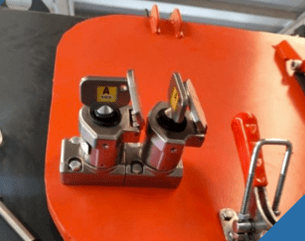

STI Safety Locks on Maintenance Doors are Standard All GRAU Concrete Mixers are equipped with STI Safety Locks. The operator can not open the mixer maintenance door without cutting off the main power and removing the key from the control cabinet. It provides a much better safety control for your personnel.

-

Mini Mobile - G30M

Small Footprint 30-45 m3/h On-Site Optional Concrete Belt Economical Towable Trailer -

G60M/G100M

Small Footprint 60-100 m³/h Optional Feeding System On-Site High Capacity High Performance -

Pro Mobile - G120M

Larger Footprint 100-120 m³/h Separate Aggregate Bins High Capacity High Performance Mass Production

| TECHNICAL SPECIFICATION | G30M | G60M | G100M | G120M |

|

Theoretical Output Compacted Mixed Concrete |

30 m³/h | 60 m³/h | 100 m³/h | 120 m³/h |

| Mixer Type | Planetary, Singleshaft | Single/Twin Shaft, Planetary | Twinshaft | Twinshaft |

| Mixer Capacity | 0.5 m³ | 1.0 m³ | 2.0 m³ | 3.0 m³ |

| Cement Weighing Bin | 300 kg | 600 kg | 1000 kg | 1500 kg |

| Water Weighing Bin | 300 kg | 300 kg | 750 kg | 750 kg |

| Additive Weighing Win | 20 kg | 20 kg | 20-50 kg | 20-50 kg |

| Maximum number of aggregate bins | 4 | 4 | 4-6 | 4-6 |

| Maximum capacity of each aggregate bin | 6 m³ | 10 m³ | 15 m³ | 30 m³ |

| Total capacity of the aggregate bins | 16 m³ | 40 m³ | 60 m³ | 120 m³ |

| Total Power | 47 kW | 65 kW | 105-110 kW | 195-200 kW |

| Date | Title | |

| 29-10-2024 | GRAU Mobile Concrete Plants |