IMPACT CRUSHERS

GRAU IMPACT CRUSHERS

Grau Impact Crushers offer high production capacity and high reduction ratios for crushing non-abrasive, soft to mildly hard material, like limestone, quartz, dolomite or gypsum.

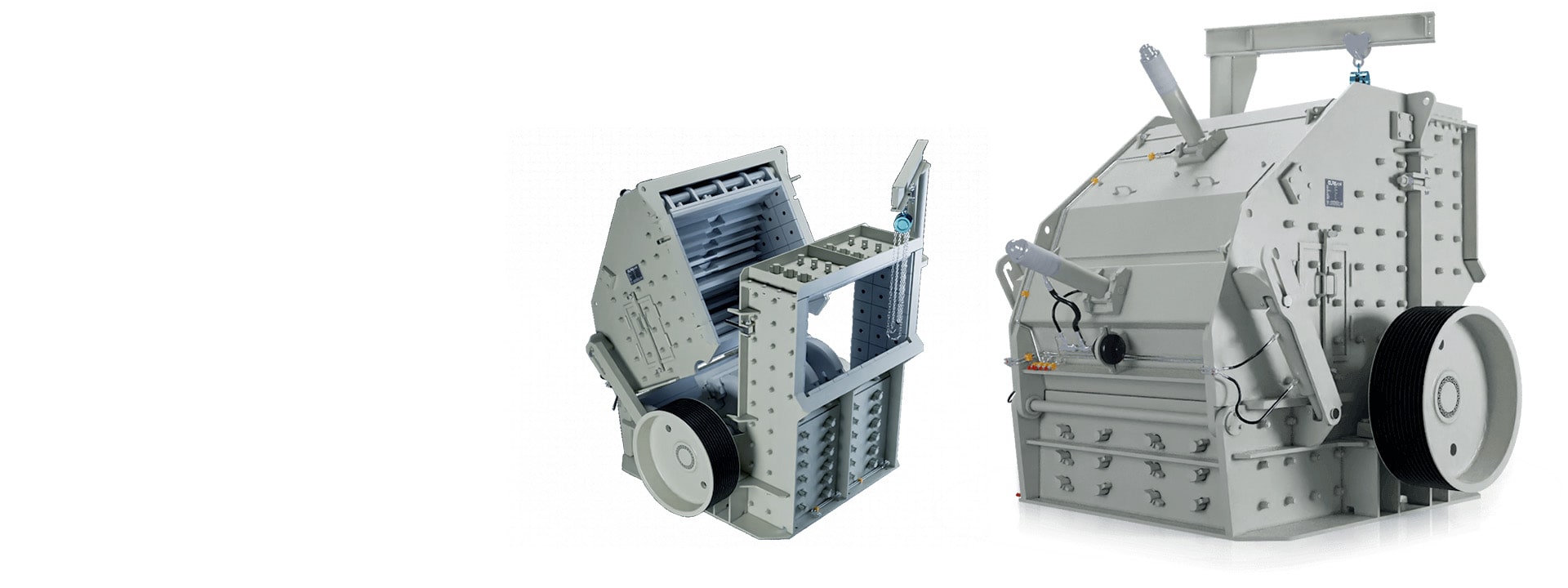

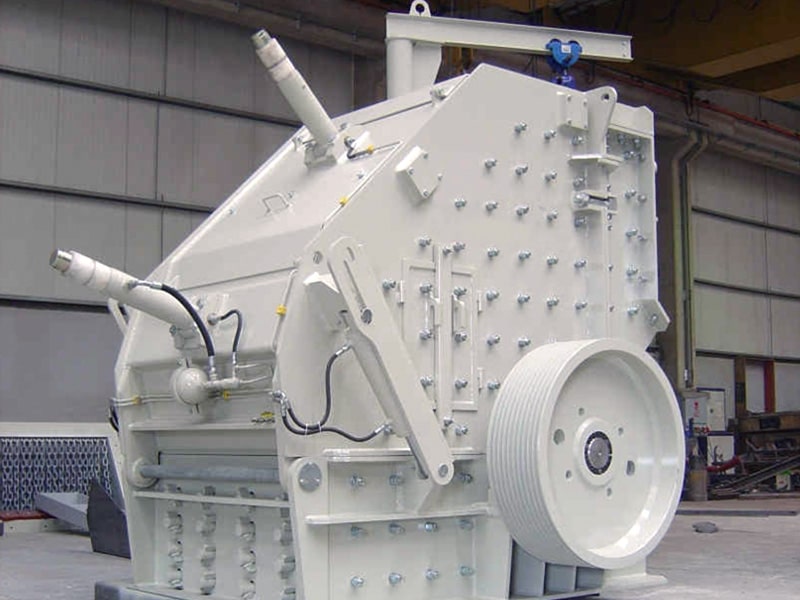

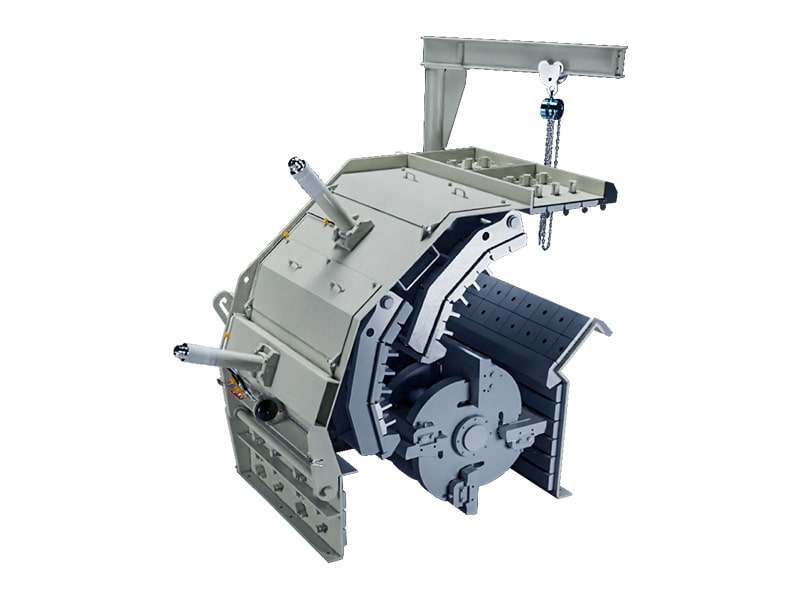

HORIZONTAL SHAFT IMPACTORS

Horizontal Shaft Impactors are the most common type of impact crushers. They perform very well in crushing non-abrasive, soft to mildly hard material in primary and secondary crushing stages and in recycling applications, like concrete or asphalt.

HIGH REDUCTION RATIO

Horizontal Shaft Impact Crushers are equipped with 3 or 4 bar rotors which keep the material inside the crushing chamber long enough to ensure effective reduction crushing. Impactors can produce relatively small material, considering their large feed opening.

PERFECTLY CUBICAL SHAPE

Horizontal Shaft Impactors have a unique ability to create homogeneous and perfectly cubical shape output product. This makes them a perfect choice for producing aggregates for concrete, asphalt and sub-base laying applications.

-

01 RELIABLE -

02 EASY ACCESS & MAINTENANCE -

03 HEAVY-DUTY WELDED ROTOR

-

Unique Operational Advantages GRAU Impact crushers come with many operational advantages. Stress-relieved heavy-duty rotors ensure long-term durability, interchangeable breaker plate liners reduce the operational costs and hydraulically operated crusher body provides easy maintenance. -

Two or Three Breaker Plates Impact Crushers come with two breaker plates as standard, but a third breaker plate can be implemented to increase the reduction ratio, increase the fines in the output and eliminate the necessity for the third crushing stage.

-

Effective Metal Protection All GRAU Impact Crushers are equipped with effective protection against unbreakable parts, like metal or hard rocks. This ensures proper protection for the rotor and other crushers elements.

| MODEL | ROTOR DIAM | ROTOR WIDTH | MOTOR POWER | MAXIMUM FEEDING SIZE | CAPACITY | |||||

| GSI 1205 | Ø1250 | 49'' | 500mm | 20'' | 100HP | 75kw | 350mm | 14'' | 60-100mtph | 66-110stph |

| GSI 1210 | Ø1250 | 49'' | 1000mm | 39'' | 220HP | 160kw | 550mm | 22'' | 140-200mtph | 150-220stph |

| GPI 1210 | Ø1250 | 49'' | 1000mm | 39'' | 270HP | 200kw | 700mm | 26'' | 140-350mtph | 155-385stph |

| GSI 1212 | Ø1250 | 49'' | 1250mm | 49'' | 270HP | 200kw | 550mm | 22'' | 160-250mtph | 180-275stph |

| GPI 1212 | Ø1250 | 49'' | 1250mm | 49'' | 270HP | 200kw | 700mm | 26'' | 160-500mtph | 180-550stph |

| GSI 1215 | Ø1250 | 49'' | 1500mm | 59'' | 250HP | 250kw | 550mm | 22'' | 250-350mtph | 275-385stph |

| GSI 1220 | Ø1250 | 49'' | 2000mm | 78'' | 540HP | 400kw | 550mm | 22'' | 350-600mtph | 385-660stph |

| GPI 1415 | Ø1400 | 55'' | 1500mm | 59'' | 350HP | 250kw | 1000mm | 39'' | 250-600mtph | 275-660stph |

| GPI 1620 | Ø1600 | 63'' | 2000mm | 78'' | 540HP | 400kw | 1000mm | 51'' | 600-900mtph | 660-990stph |