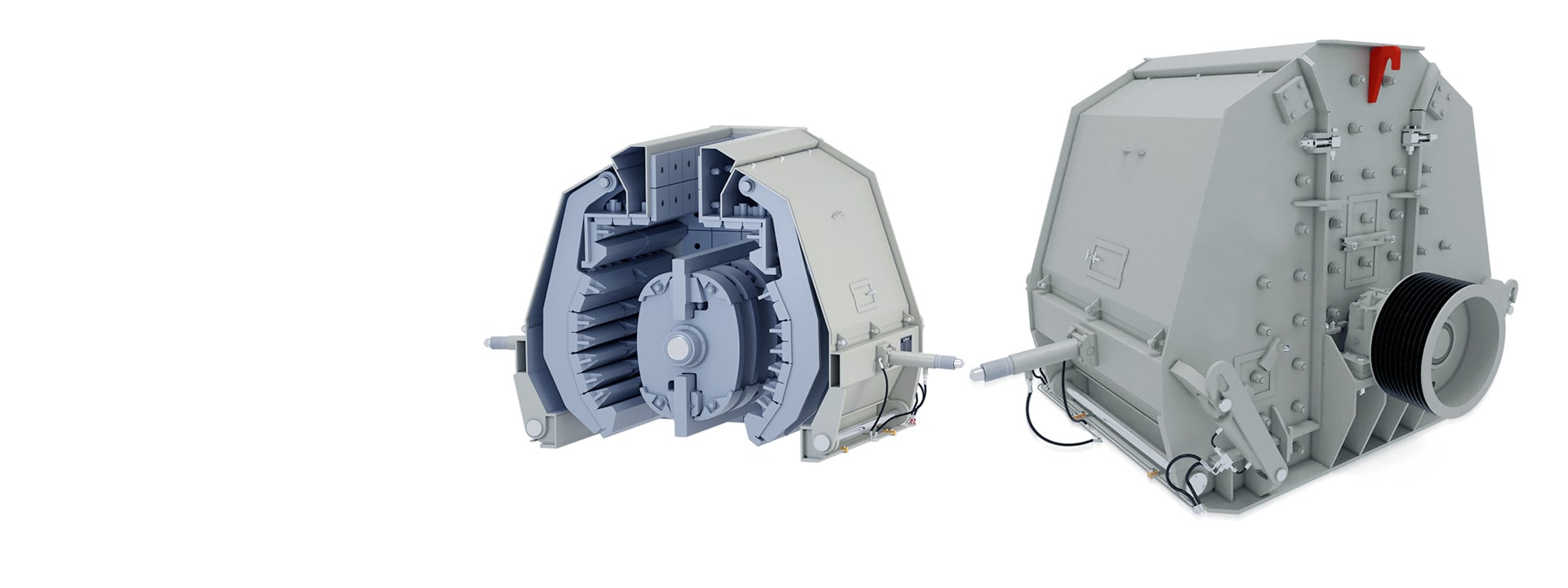

REVERSIBLE IMPACT CRUSHERS

REVERSIBLE IMPACT CRUSHER – GRAU

GRAU Reversible Impact Crushers have been designed for crushing soft and relatively hard material. They are mostly used in third crushing stage and can produce high volumes of fines.

GRAU REVERSIBLE HORIZONTAL SAFT IMPACTORS

Also known as Tertiary Impact Crushers, Reversible Impact Crushers excel in producing fines and cubical shape final product due to their high rotor speeds.

PERFECTLY FINE OUTPUT

GRAU Reversible Impact Crushers are a perfect choice for manufacturing sand and other powders from non-abrasive limestone, quartz, dolomite or gypsum.

PERFECTLY CUBICAL SHAPE

Depending on the setup, GRAU Reversible Impact Crushers can be adjusted for producing high volume on chipping material which is a perfect choice for manufacturing asphalt and sub-base stabilisation mixes.

WHY GRAU REVERSIBLE IMPACT CRUSHERS?

Reliable

Easy Access and Maintenance

Oval-Shaped Welded Rotor.

-

01 RELIABLE -

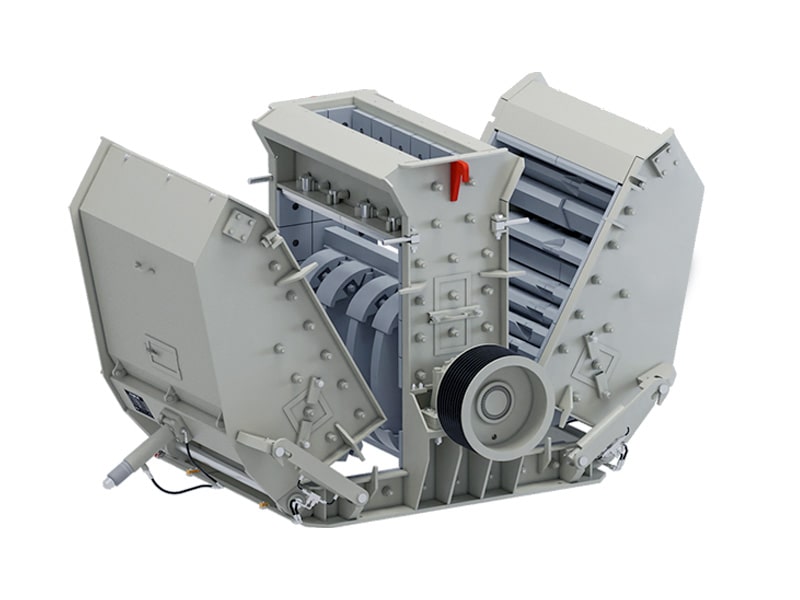

02 EASY ACCESS & MAINTENANCE -

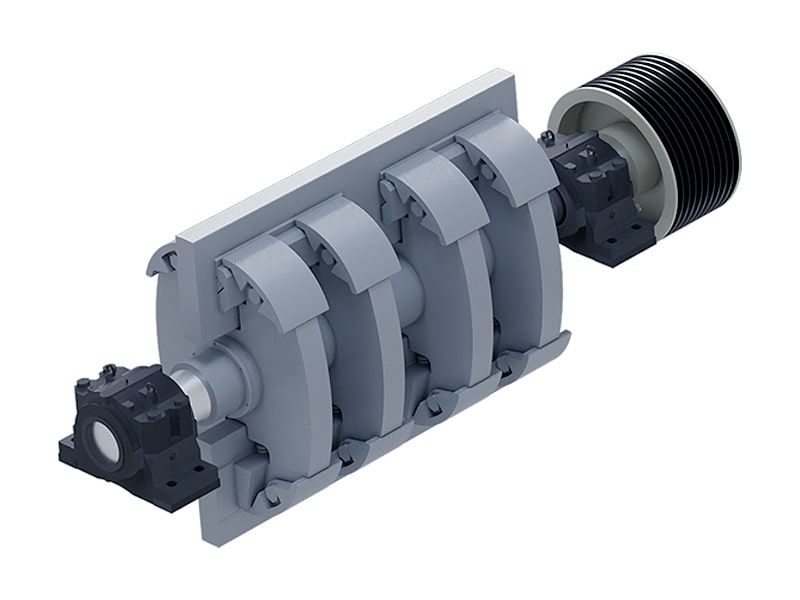

03 OVAL-SHAPED WELDED ROTOR

-

Unique Operational Advantages GRAU Reversible Impact crushers come with many operational advantages. Stress-relieved heavy-duty oval-shaped rotors ensure long-term durability and high impact strength, interchangeable breaker plate liners reduce the operational costs and hydraulically operated crusher body which opens on both sides of the crusher provides easy maintenance. -

Special Shape Rotor Heavy-Duty stress-relieved welded oval-shaped rotor has been designed for high impact strength. This shape applies higher force compared to standard round rotors which results in better reduction ratio and lower grinding effect.

-

Easy Service Hydraulically operated crusher body opens on both sides of the crusher which provides easy maintenance and easy access to all the wear parts. The same hydraulic system is used for adjusting the position of the breaker plates.