ROLL CRUSHERS

WHAT IS A ROLL CRUSHER?

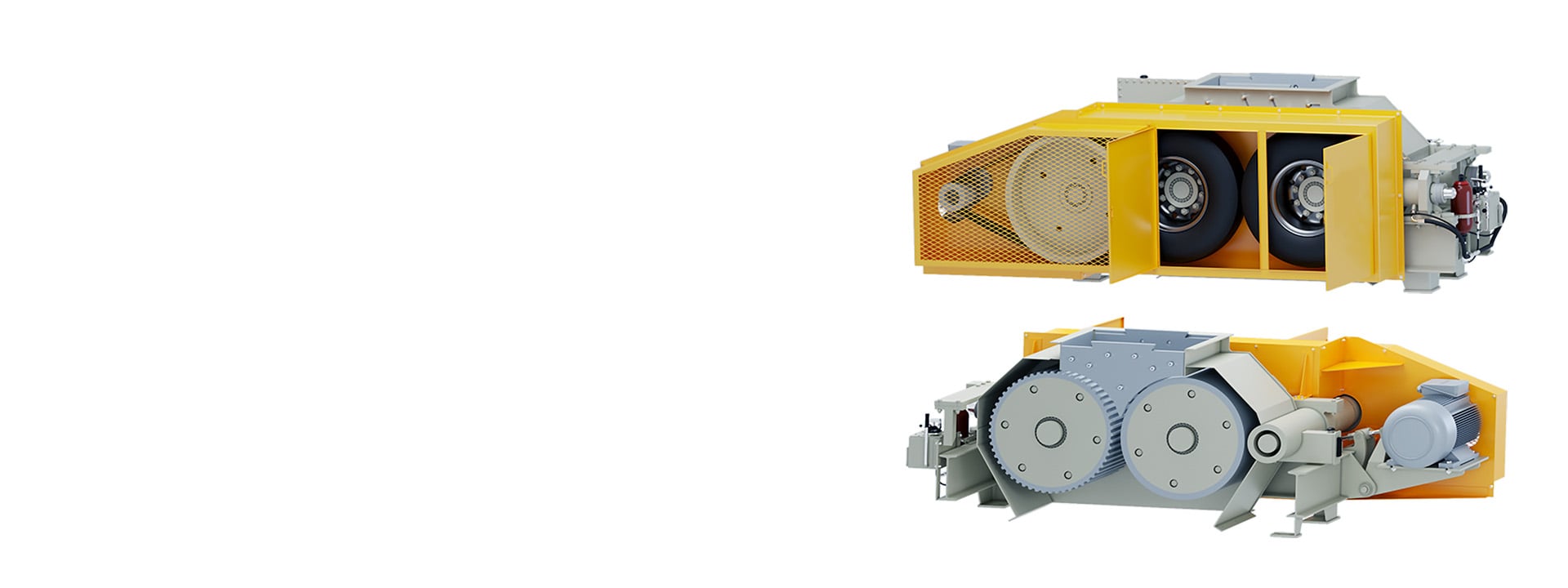

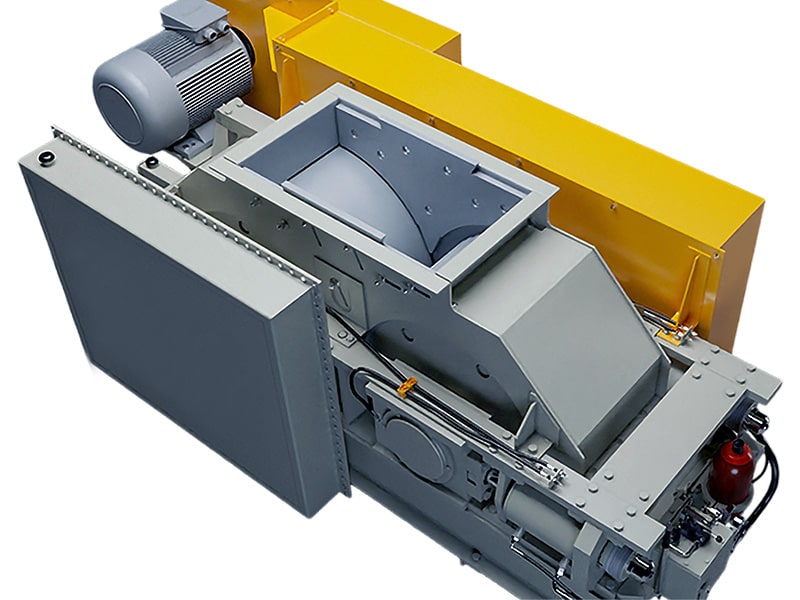

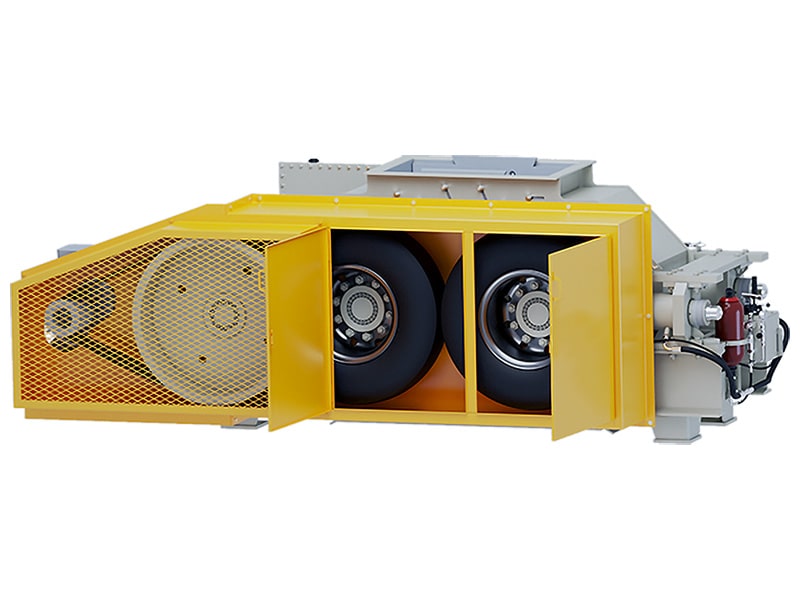

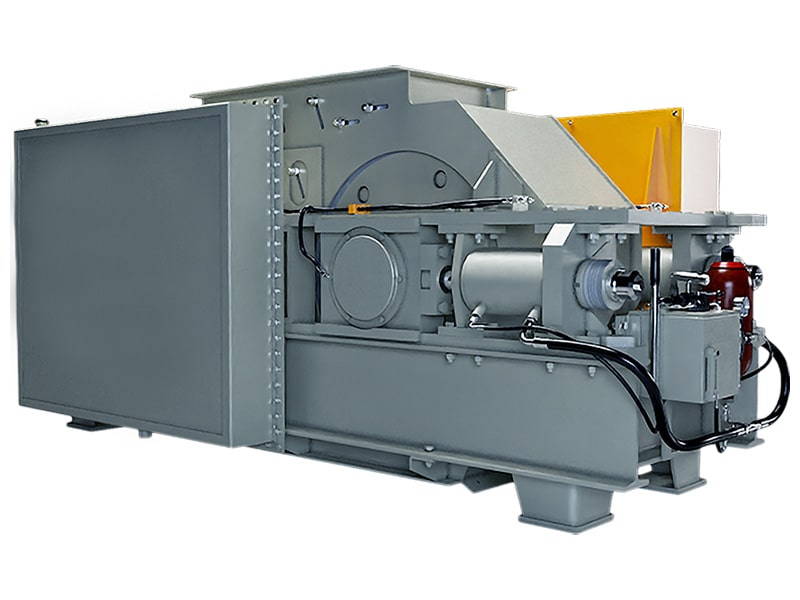

Roll Crushers are unique machines which crush material by means of compression between two parallel cylinders that rotate in opposite directions. They can handle wet and sticky material while generating minimum amounts of fines and producing great cubical product. This makes them very useful in mining applications.

EFFECTIVE CRUSHING

The amount and size of material that the roller crusher can handle varies depending on the gap distance between the rollers. According to the desired material size, GRAU Roll Crushers can be designed to have large feed openings, enabling an effective capacity increase.

GRAU ROLL CRUSHER ADVANTAGES

- High throughput capacity

- Accepts large feed sizes while producing small product sizes

- Cubicle product with minimal fines

- A variety of roll tooth profiles available

- Adjustable for change in product sizing

- Automatic tramp relief

- Minimal maintenance required

- Low cost per ton operation

Why GRAU ROLL CRUSHERS?

-

01 HIGH CAPACITY -

02 MINIMUM FINES -

03 LOW MAINTENANCE

-

Versatile Crushing Chamber The design of the crushing chamber (flat or screwed arrangement of the crushing tools) is selected to suit the desired application and the arrangement in relation to the flow of material. Options are available for fine, medium and coarse material thanks to replaceable toothpicks and teeth rings. -

High Throughput Rates The distance between the rollers can be adjusted between the upper and the lower limits according to the desired size of the material. If the gap increases, the capacity increases accordingly. The crushers can be adjusted for different type of material, material hardness and moisture content.

-

Low Operational Costs Each GRAU Roll Crusher is equipped with a hydro-pneumatic protection system that provides advanced protection against non-crushable materials. Rollers and linings are made of wear-resistant manganese alloyed cast steel and shaft bearings are equipped with special labyrinth system that keeps the dust off the bearings and prolongs their service life. It all results in consistent results with low operational costs.

PRODUCT HIGHLIGHTS AND TIPS

Contact Us

GRAU Technic team is here to listen to your comments and suggestions.

Rest assured with GRAU's commitment to quality and customer satisfaction. With every GRAU product our customers get a comprehensive 12-month warranty against manufacturing defects. When you invest in a GRAU plant, you're not just purchasing equipment; you're investing in quality, knowledge, and experience. Our team of experts stands by our customers every step of the way, ensuring seamless operation and maximum productivity. Experience peace of mind knowing that GRAU is dedicated to delivering top-notch products and exceptional service. Our service team is always on hand to assist you, providing timely support and expertise whenever you need it. Choose GRAU for reliability, performance, and unparalleled customer service. Elevate your operations with confidence, backed by GRAU's unwavering Passion to do Better.