RECIPROCATING PLATE FEEDERS

GRAU RECIPROCATING PLATE FEEDERS

WHAT IS A RECIPROCATING PLATE FEEDER?

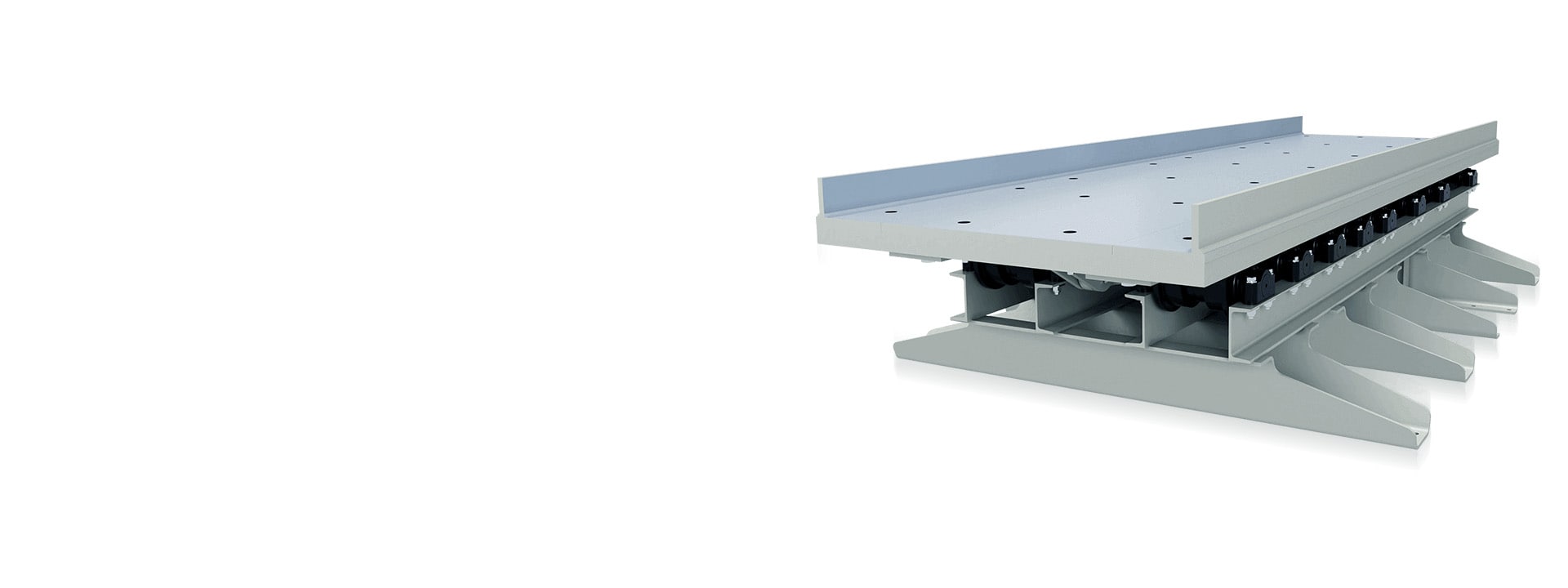

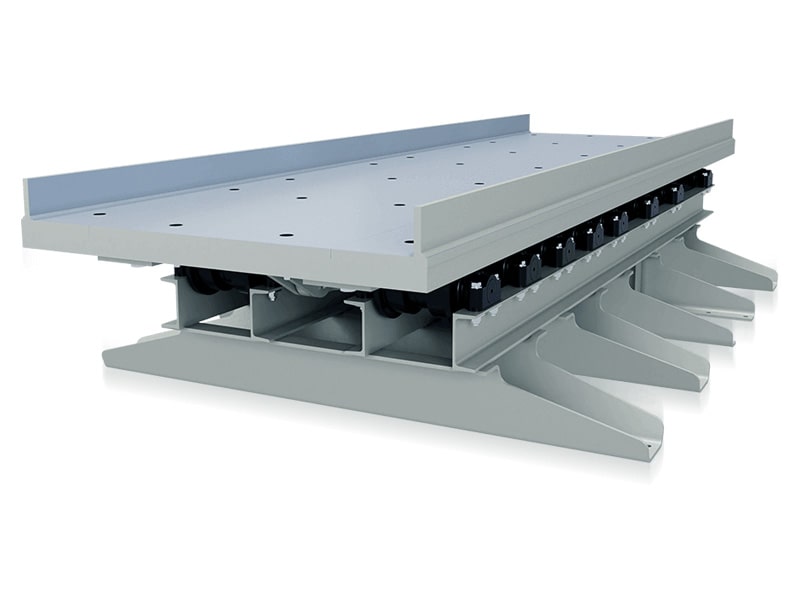

A Reciprocating Plate Feeder consists of a frame with a thick wear-resistant steel sheet plate at the top. The frame with the plate moves back and forth with the help of a hydraulic piston drive. When plate comes forward the gap at the rear end gets filled with material and when the plate goes backward a portion of material gets discharged. The frame sits on a set of bearings that don’t require maintenance or lubrication.

A GOOD ALTERNATIVE FOR APRON FEEDERS

Reciprocating Plate Feeders can handle large feed size which can be discharged from higher levels as there is always material on the plate which relives the impact. These feeders can handle wet and sticky material, can withstand strong impacts similar to Apron Feeders, yet they are more economical and require less maintenance.

-

01 ROBUST -

02 LESS MAINTENANCE -

03 RELIABLE

-

Operational Advantages GRAU Reciprocating Plate Feeder components require less maintenance compared to other types of feeders. High impact resistance allows for faster damping from higher levels and hydraulic drive system allows changing the stroke and speed of the piston remotely giving full control over the feed rate. -

Why GRAU Reciprocating Plate Feeders? GRAU is committed to helping our customers select a Reciprocating Plate Feeder that will offer the highest level of reliable performance, accuracy and consistency. We work closely with our customers to make sure we meet all the specific requirements. Developed for easy maintenance, transport and installation, our Reciprocating Plate Feeder rugged design and features provide a significantly increased service life.