VIBRATING FEEDERS

GRAU VIBRATING FEEDERS

WHAT IS A VIBRATING FEEDER?

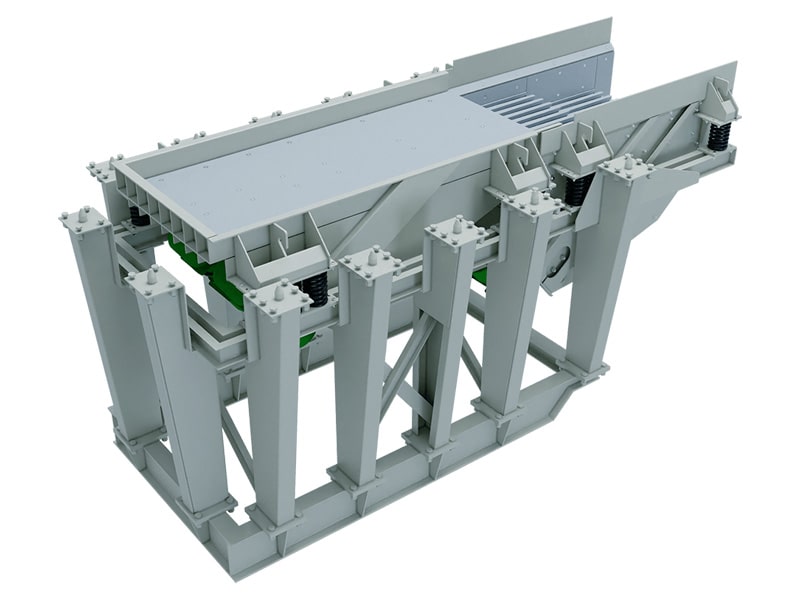

A vibratory feeder is a piece of equipment that uses vibration and gravity to create a constant material flow for further processing by the crushers or screens. Gravity is used to direct the material flow while powerful vibrators force the material to move. This setup allows to move large amounts of material at a constant speed.

VIBRATING FEEDERS WITH GRIZZLY SCALPERS

Primary vibrating feeders can be equipped with grizzly bars which reduce the amount of undersized material going into the crusher by scalping it off during the feeding process. The opening between the grizzly bars can be adjusted to suit the application.

GRAU VIBRATING FEEDER ADVANTAGES

-

Adjustable grizzly bar spacing to suit various crusher types and settings

-

A variety of liner materials are available

-

Customized grizzly sections, including punch plate, fabricated bars and rubber media

-

Allows for smaller, less expensive crushers to be selected by scalping out the undersize from the feed

-

01 HEAVY-DUTY -

02 ADJSUTABLE BAR SPACING -

03 PERFECT SCALPING

-

Diversity in Applications We manufacture and supply a few different sizes for primary and secondary feeding applications. Our Vibrating Feeders can be used under the primary feeding bins, before the secondary crushers with adjustable gates to control the flow and inside the tunnels for material extraction. GRAU engineers can design different solutions to meet your unique applications in aggregate processing, mining and recycling industries. -

Only High-Quality Components GRAU Vibrating Grizzly Feeders have a history of reliability and durability. Quality vibrators provide long-term operation with minimum maintenance, strong steel structure ensures the frame and feeder body are resistant to vibrations and grizzly bars made of highly wear resistant alloy will ensure low cost-per-ton maintenance costs.