-

Operation Tips: 1. Maintain a Consistent Feed Ensure the material is loaded evenly across the belt to prevent uneven wear and minimise belt tracking issues. Avoid sudden surges or blockages by using flow control gates where needed.

BELT FEEDER

GRAU BELT FEEDERS: CONTROLLED AND RELIABLE MATERIAL FEEDING

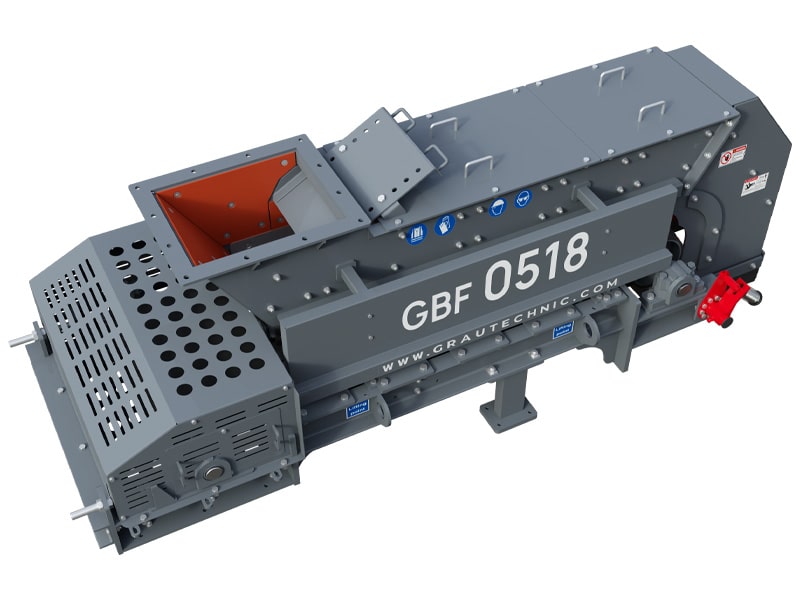

GRAU Belt Feeders (GBF) are designed for accurate and controlled feeding of bulk materials in aggregate processing, mining, quarrying, and industrial applications. Built for durability, consistency, and long service life, they provide a smooth, regulated flow of material to crushers, screens, conveyors, or other downstream equipment.

Unlike conventional conveyors, GRAU Belt Feeders are specifically engineered to operate under hoppers or bins, where variable feed rates and heavy loads require a robust, consistent feeding solution. With a compact footprint and durable design, they integrate easily into existing setups and are available in various sizes to suit different materials and flow requirements.

GBF models are ideal for handling sand, gravel, crushed rock, recycled material, coal, and other bulk solids, offering uniform discharge while minimising surges and blockages. Their low maintenance needs and precise control make them a smart choice for continuous operations.

WHAT IS A BELT FEEDER?

A belt feeder is a type of conveyor used to feed bulk materials at a controlled rate. It consists of a belt running over pulleys and supported by rollers or slider beds, positioned beneath a bin, hopper, or surge pile. Unlike a conveyor, which simply transports material, a belt feeder regulates the flow, making it ideal for dosing, blending, or steady discharge to processing equipment.

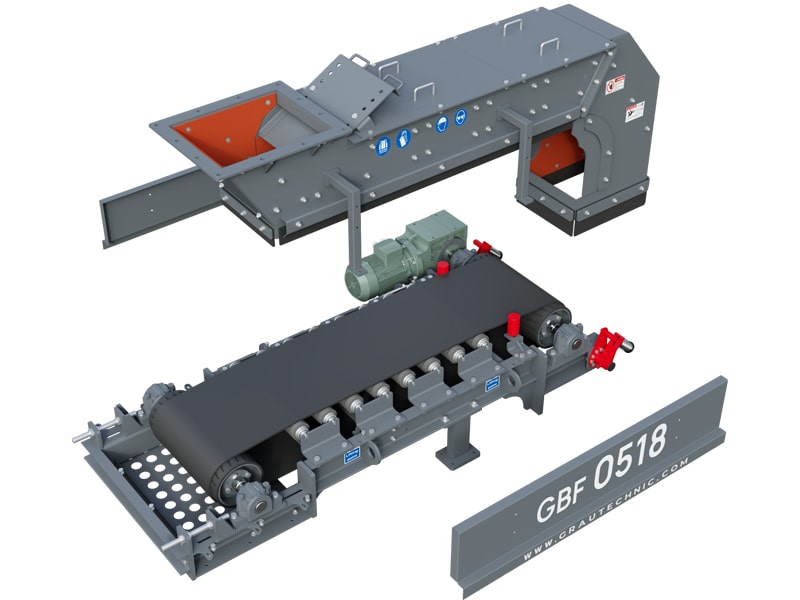

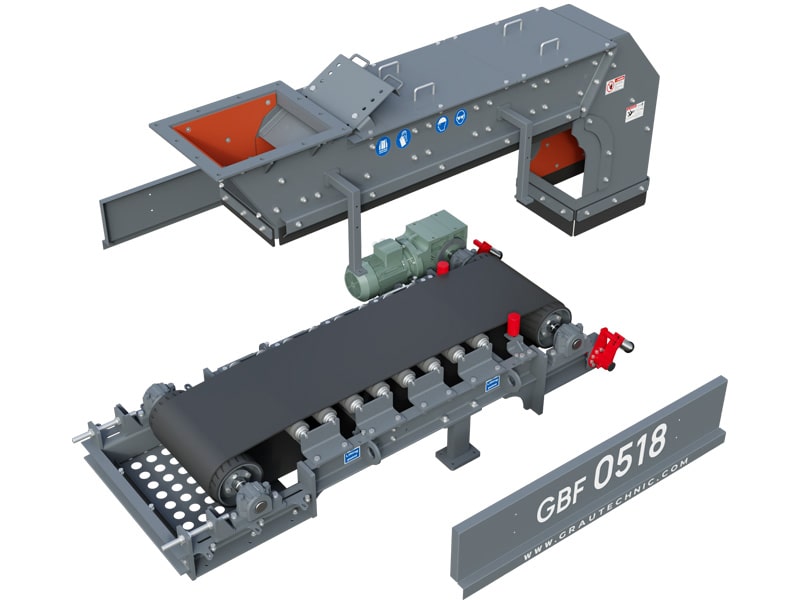

WHAT DOES A BELT FEEDER CONSIST OF?

A typical belt feeder includes a heavy-duty frame, a head and tail drum, drive motor, belt tensioning system, and idlers or sliders to support the belt. It may also feature skirting, liners, belt scrapers, and variable speed controls. The frame is usually placed under a storage hopper, designed to handle high loading pressures while maintaining a constant feed rate.

HOW DO BELT FEEDERS WORK?

Belt feeders operate by running a flat or chevron type belt at a controlled speed under a bin or hopper. As material flows onto the belt from above, the feeder regulates the volume discharged based on belt speed and load height. The belt’s speed can be fixed or variable, depending on the application. This smooth, consistent feed helps prevent equipment overload, surging, or inconsistent material flow downstream.

WHAT ARE THE APPLICATION AREAS FOR BELT FEEDERS?

- Quarrying and Mining – Feeding crushers, screens, or conveyors with a steady flow of mined rock, ore, or minerals.

- Sand and Gravel Plants – Regulating material flow from bins to washing or screening equipment.

- Recycling Facilities – Handling crushed concrete, asphalt, and other recycled materials.

- Bulk Material Handling – Feeding coal, grain, fertiliser, cement, or similar materials in ports, terminals, or storage yards.

- Blending and Dosing Systems – Delivering precise amounts of material in mixing or batching operations.

-

01 RELIABLE & DURABLE -

02 CONSTANT FEED RATE -

03 STEADY FLOW

-

Modular and Robust Frame Built on a rigid, modular steel frame, GRAU Belt Feeders offer high structural durability while allowing easy transport and installation. The design accommodates site-specific needs and ensures long-term stability under heavy-duty operating conditions. -

High-Quality Bearings All GBF series belt feeders are fitted with premium-grade, heavy-duty bearings to ensure smooth, reliable operation under continuous load. These components are selected for long service life, low maintenance, and resistance to contamination from dust and moisture.

-

In-House Designed Drive and Tail Drums GRAU designs and manufactures its own drive and tail drums to exacting standards, ensuring perfect alignment, durability, and performance. This control over drum geometry and surface finish helps reduce belt wear and slippage, improving long-term reliability. -

Impact Rollers To absorb the force of material dropping from above, GBF feeders are equipped with impact rollers at the loading zone. These rollers protect the belt from damage, reduce shock loads, and extend the lifespan of both the belt and the support structure.

-

Fully Equipped with Chutes and Slide Gates Each belt feeder is delivered complete with heavy-duty feed chutes and manually or hydraulically operated slide gates for flow control. This integrated design allows for quick installation and precise regulation of discharge volume from hoppers or bins. -

Optional Variable Speed Drives For applications requiring fine control over material flow, GBF feeders can be fitted with variable speed drives. This feature enables precise adjustment of feed rate, making the system suitable for batching, blending, or sensitive downstream processes.

-

Operation Tips: 2. Monitor Belt Tension and Alignment Check belt tension regularly to prevent slippage and excessive wear. A properly aligned belt runs smoother, reduces energy loss, and extends the life of rollers, bearings, and the belt itself.

-

Operation Tips: 3. Inspect Bearings and Rollers Frequently Look for signs of wear, overheating, or contamination in the bearings and rollers. Lubricate as recommended and replace damaged components promptly to avoid further mechanical issues.

-

Operation Tips: 4. Keep the Feeding Section Clean Regularly remove material build-up from chutes, pulleys, and under the belt. Accumulated fines or sticky materials can cause belt misalignment, premature wear, or motor overload.

-

Operation Tips: 5. Check Drive Components Inspect the motor, gearbox, and drive pulleys for noise, vibration, or unusual movement. Tighten loose fasteners and ensure guards are in place to maintain safe and reliable operation.

-

Operation Tips: 6. Follow a Preventive Maintenance Schedule Stick to a routine that includes daily visual checks, weekly mechanical inspections, and scheduled servicing. Proactive maintenance reduces downtime and extends the life of your belt feeder.