-

Operation Tips: Maintain a Steady Feed Rate Ensure material is fed steadily across the full width of the screen. A consistent feed improves water removal and prevents uneven wear on screen media. Sudden surges or dry spots can reduce efficiency and affect product quality.

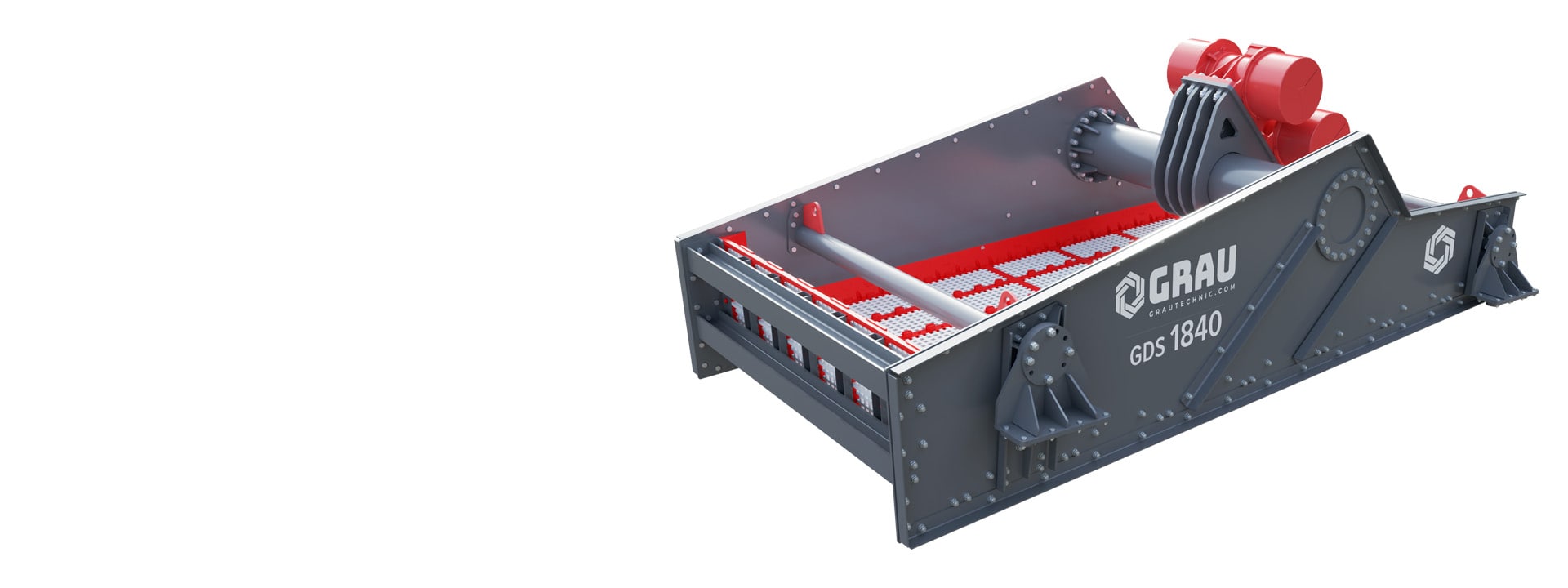

DEWATERING SCREEN

GRAU DEWATERING SCREENS

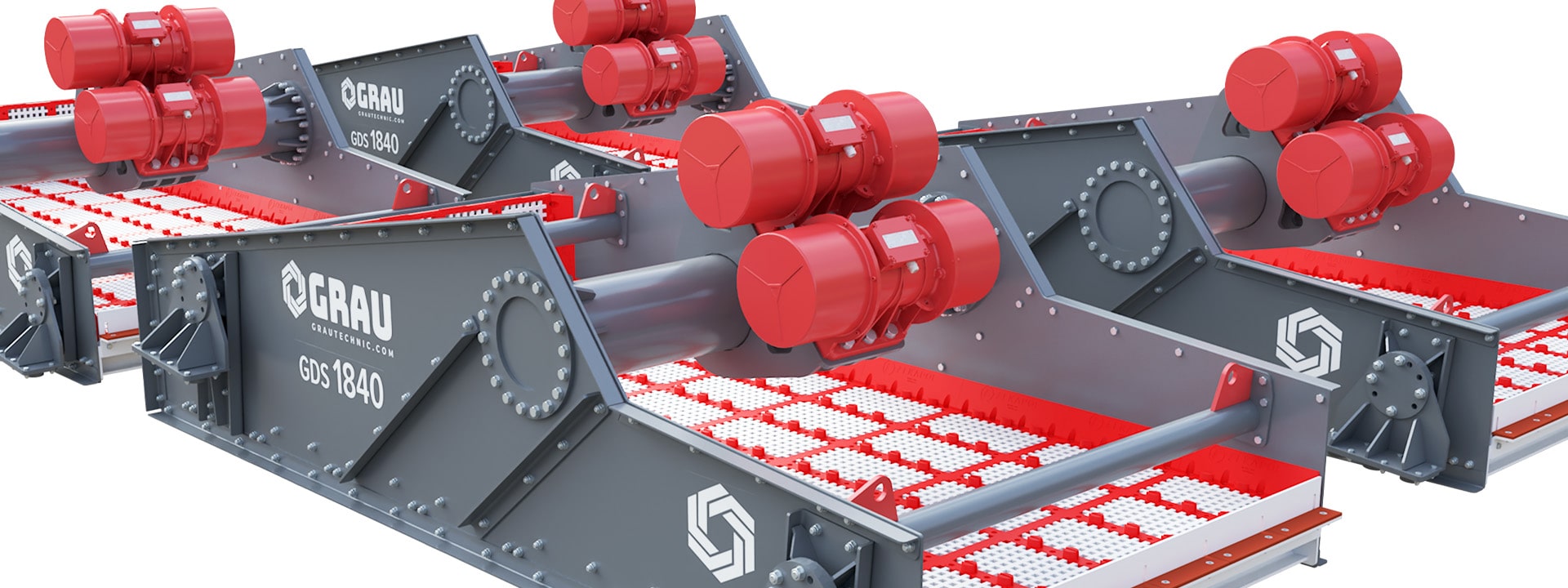

GRAU GDS Series Dewatering Screens have been designed to remove excess water from sand, gravel, and other fine aggregates after washing. They deliver a drier, cleaner end product with reduced moisture content, improving material handling and speeding up stockpiling or loadout. Commonly used in sand plants, recycling yards, and quarrying operations, they help increase productivity and reduce drying time and associated costs. Paired with suitable slurry pumps and cyclones GRAU Dewatering Screens can be used in compact sand plants.

WHAT IS A DEWATERING SCREEN?

A dewatering screen is a type of vibrating screen used to separate water from solid materials. It is typically installed at the end of a washing process to remove surface water from the final product. The result is a material with a low moisture content that can be handled, stockpiled, or transported immediately without the need for additional drying.

WHAT DOES A DEWATERING SCREEN CONSIST OF?

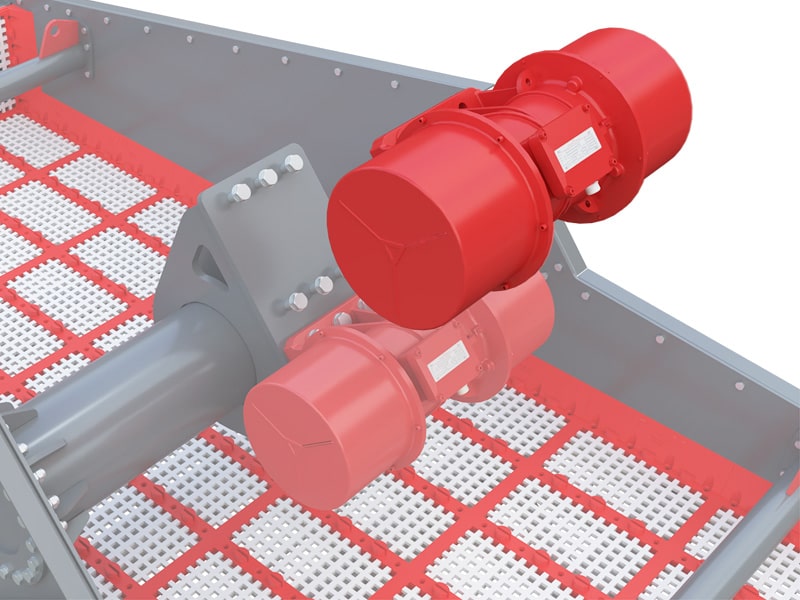

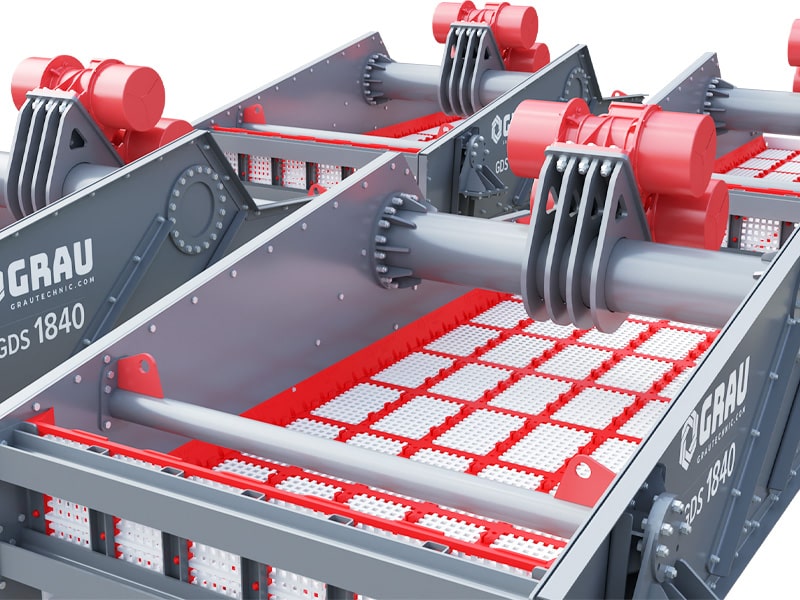

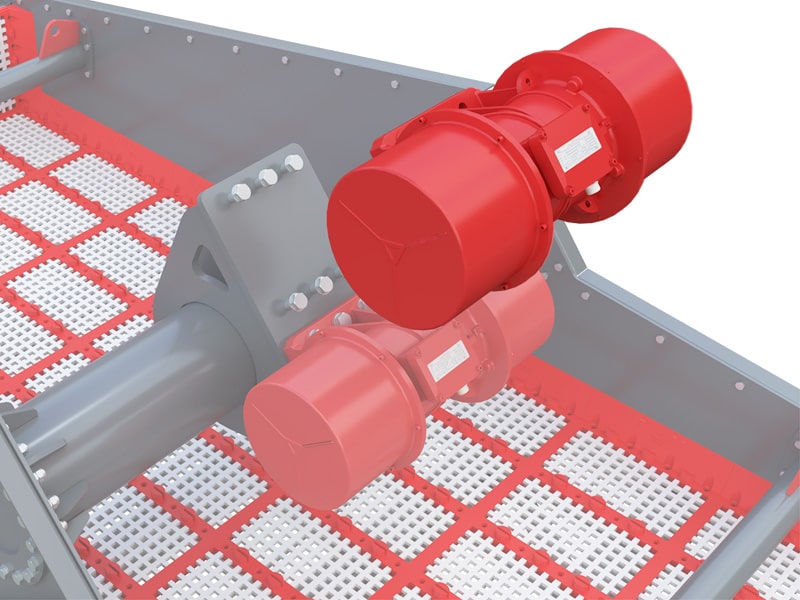

A standard dewatering screen includes a sloped deck fitted with high-tension screening media, usually polyurethane or rubber. It uses twin vibratory motors mounted either directly on the screen frame or on a base structure. The motors create a linear motion that drives the wet material up the screen slope while water drains through the screen surface at the bottom. Side walls, support springs or rubber mounts, and adjustable discharge lips are part of the assembly.

HOW DO DEWATERING SCREENS WORK?

Dewatering screens use vibration to lift and move wet material up and over a screening surface. The high-frequency, low-amplitude vibration forces water out of the material and through the screen media. As the material travels up the incline, capillary action and gravity continue to draw out water, leaving behind a drier product. The result is a consistent, manageable material with moisture levels as low as 8–15%, depending on the feed.

WHAT ARE THE MAIN APPLICATIONS AREAS FOR DEWATERING SCREENS?

GRAU dewatering screens offer versatile solutions across numerous industries:

-

Sand and Gravel Processing – Removing excess water from washed sand and crushed fines before stockpiling or transport.

-

Recycling Operations – Dewatering construction and demolition waste, recycled aggregates, and filter cake.

-

Mining and Minerals – Used after washing or classification to dry coal, ores, and other fine mineral products.

-

Concrete and Asphalt Plants – Producing drier material for consistent mix quality and easier handling.

-

Industrial Sludge Treatment – Reducing moisture content in slurry and sludge for more efficient disposal or further processing.

-

01 HIGH EFFICIENCY -

02 EXCEPTIONAL DRYING -

03 COST EFFECTIVE

-

Highly Efficient Dewatering GRAU Dewatering Screens are engineered to achieve low moisture levels in the final product, often between 8–15%. This helps reduce or eliminate the need for further drying, speeds up stockpiling, and ensures faster loading and transport. The result is cleaner, drier material that’s easier to handle and meets industry standards. -

Precise Vibration Control Each unit is equipped with twin vibratory motors that generate a controlled linear motion. This motion helps lift the material while encouraging water to drain efficiently through the screen surface. The motor speed and the screen angle can be adjusted to match the feed material and desired moisture level, ensuring stable and accurate results.

-

Unique Design Robust Structure Built using high-quality vibration resistant steel components, our dewatering screens are made for long-term use in tough working conditions. The weight has been carefully adjusted so that more vibration has been transferred to the material ensuring higher throughput compared to heavier bulky competitor screens. Whether used in sand plants, quarries, or recycling operations, the rugged design ensures consistent performance and reduced downtime due to wear or structural fatigue. -

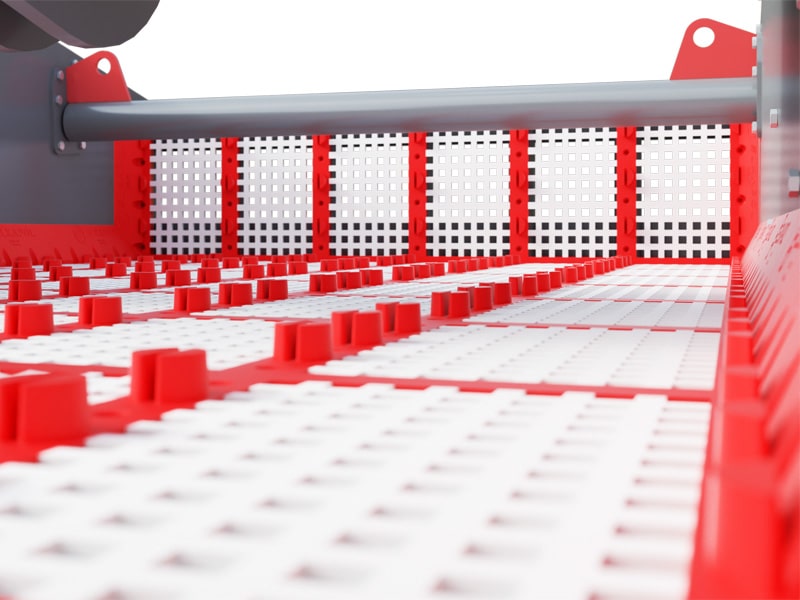

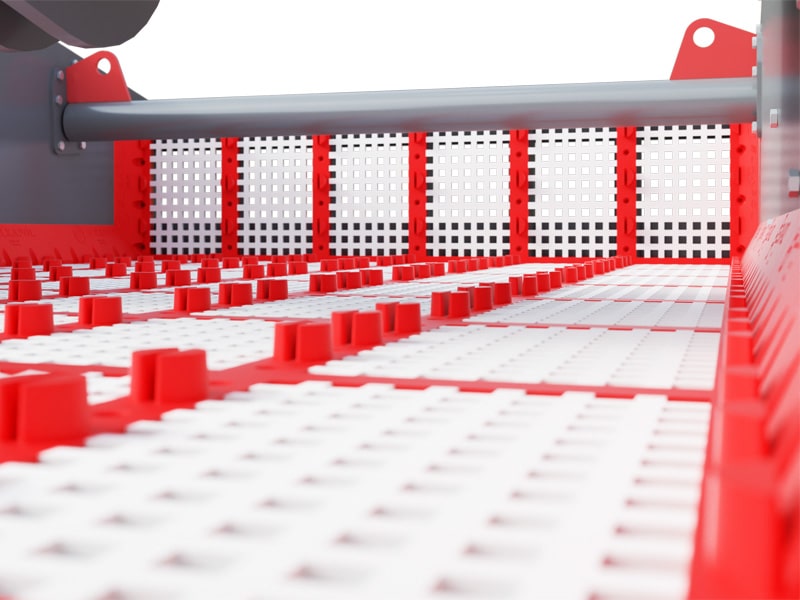

Modular Screen Media Fitted with high-quality, modular screen panels – usually made from wear-resistant polyurethane – GRAU Dewatering Screens allow for easy replacement and customization. Different panel sizes and configurations can be used to match specific material types and capacities, helping optimise performance and reduce maintenance time.

-

Versatile Applications GRAU Dewatering Screens can handle a wide variety of materials, including washed sand, crushed stone, recycled aggregates, and fines from construction and demolition waste. They are ideal for use in both new installations and upgrades, offering flexibility for producers across different sectors.

-

Operation Tips: Monitor Vibration Settings Check that the vibratory motors are running at the correct speed and angle. Proper vibration ensures effective movement of material and allows water to separate efficiently. Over time, worn motor mounts or incorrect settings can reduce performance.

-

Operation Tips: Adjust Discharge Lip if Needed Use the adjustable discharge lip to control the dryness of the final product. Raising the lip can hold material on the screen longer, increasing drying time, while lowering it can allow faster discharge if the material is already dry enough.

-

Maintenance Tips: Inspect Screen Panels Regularly Look for signs of wear, tears, or blinding on the screen media. Damaged panels reduce drainage efficiency and may allow oversize or wet material through. Replace worn panels promptly to maintain consistent output. We use modular PU panels on all GRAU dewatering screens which will allow you to change individual section if required.

-

Maintenance Tips: Clean Build-up Frequently Keep the screen deck and discharge area free from material build-up. Accumulated fines or sludge can block water flow and put strain on the machine. A quick daily clean-down keeps performance high and avoids downtime.

-

Maintenance Tips: Check for Loose Bolts and Components Vibration can gradually loosen fittings, so inspect the screen frame, motor mounts, and fasteners regularly. Tightening components early prevents damage and ensures stable, safe operation.

-

Follow a Maintenance Schedule Stick to a planned maintenance routine, including motor checks, lubrication, screen panel inspection, and frame cleaning. Regular upkeep ensures long-term performance, reduces unexpected stops, and extends the life of the equipment. Please refer to user manual or contact our service department if required.

|

MODEL

|

Dimensions

|

Vibrator Power

|

No of Decks

|

Weight

|

Screen Panels

|

|||

|

mm

|

ft

|

kW

|

HP

|

kg

|

lbs

|

|||

|

GDS 1224

|

1200x2400

|

4x8

|

2x2.88

|

2x3.7

|

1

|

1720

|

3790

|

PU

|

|

GDS 1824

|

1800x2400

|

6x8

|

2x5 | 2x6.7 |

1

|

2250

|

4960

|

PU

|

|

GDS 1840

|

1800x4000

|

6x13

|

2x6.1

|

2x8.2

|

1

|

3450

|

7605

|

PU

|